Fish Waste Liquid Fertilizer Plant for Drip Irrigation System

The global demand for sustainable agriculture has increased the importance of recycling organic by-products into valuable resources. One of the most promising innovations is the fish waste liquid fertilizer plant for drip irrigation system, which converts fish residues into nutrient-rich liquid fertilizers. Unlike traditional solid fertilizers, liquid fertilizers derived from fish waste are easily absorbed, environmentally friendly, and highly effective for precision irrigation methods such as drip systems.

By establishing a fish waste liquid fertilizer plant for drip irrigation system, aquaculture industries, fisheries, and farmers can close the loop between food production and waste management. The result is a fertilizer that not only reduces pollution but also enhances soil fertility and crop yields.

Nutrient-Rich Composition: Fish waste is high in nitrogen, phosphorus, potassium, and trace minerals such as calcium and magnesium—ideal for crop nutrition.

Sustainability: Recycling fish by-products minimizes waste disposal issues in aquaculture and fisheries.

Soil Health Improvement: Fish-based fertilizers enhance microbial activity, improving soil structure and long-term fertility.

Eco-Friendly Alternative: Using organic residues lowers dependence on synthetic fertilizers and reduces greenhouse gas emissions.

Compatibility with Drip Irrigation: Liquid fish fertilizers are fully soluble and can be applied directly through drip systems, delivering nutrients precisely to plant roots.

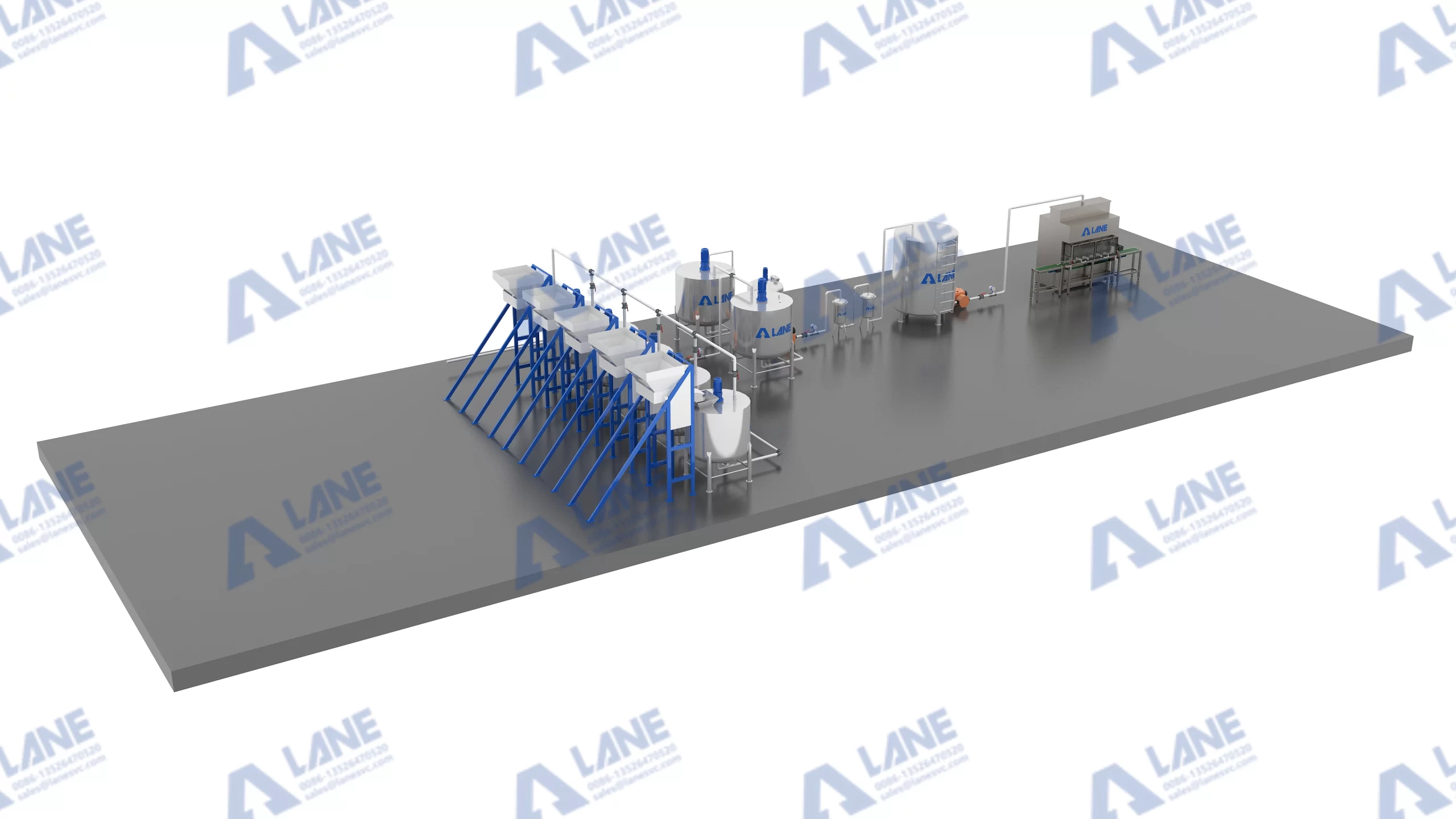

The fish waste liquid fertilizer plant for drip irrigation system follows a structured process, supported by specialized equipment:

The fish waste liquid fertilizer plant for drip irrigation system brings benefits that extend from individual farmers to entire agricultural economies. Its advantages include both direct agronomic improvements and long-term sustainability gains:

Efficient Use of Nutrients

Fish waste contains proteins, amino acids, and minerals. When processed into liquid fertilizer, these nutrients are fully soluble and delivered directly to plant roots through drip irrigation, ensuring minimal waste.

Dual Waste Management Solution

The system solves two problems simultaneously: it reduces the burden of disposing fishery by-products and decreases dependence on synthetic fertilizers in agriculture.

Support for Precision Agriculture

By integrating with drip irrigation, the plant allows farmers to fine-tune nutrient application based on crop needs and growth stages, enhancing yield and quality.

Eco-Friendly Farming Practice

Unlike chemical fertilizers that may leach into groundwater, fish-based liquid fertilizers improve soil health and microbial diversity, promoting long-term land productivity.

Economic Opportunities

Farmers and cooperatives operating a fish waste liquid fertilizer plant for drip irrigation system can supply fertilizer locally or regionally, creating new revenue streams and fostering green businesses.

In coastal regions of India, smallholder farmers partnered with fish markets to establish a fish waste liquid fertilizer plant for drip irrigation system. The plant processed leftover fish into liquid fertilizer, which was then supplied to local vegetable farms. Integrated into drip irrigation systems, the fertilizer boosted crop yields by 18% while reducing the need for costly imports of chemical fertilizers. Farmers reported improved soil fertility and stronger plant resilience against pests.

In Brazil, an agribusiness cooperative developed a large fish waste liquid fertilizer plant for drip irrigation system near major fishing ports. The facility processes hundreds of tons of fish waste annually, converting it into liquid fertilizer for soybean and maize production. The fertigation system ensures that nutrients are delivered evenly, cutting fertilizer consumption by 25% and improving sustainability practices. The cooperative also markets the product domestically and for export, creating new economic opportunities.

The environmental benefits of a fish waste liquid fertilizer plant for drip irrigation system extend across multiple dimensions.

First, it directly reduces organic pollution. Fish processing plants and markets often struggle with waste disposal, and much of the residue ends up in landfills or waterways. When these by-products decompose, they release methane and other harmful gases. By recycling fish waste into liquid fertilizer, these emissions are significantly reduced, contributing to climate change mitigation.

Second, the system prevents water contamination. Discarded fish waste dumped into rivers or seas depletes oxygen levels and disrupts aquatic ecosystems. Processing it into fertilizer eliminates this risk, protecting biodiversity in coastal and inland waters.

Third, when integrated into drip irrigation, the technology ensures fertilizers are delivered precisely to plant roots. This minimizes nutrient runoff into groundwater or nearby lakes, which is a common issue with conventional fertilizers. Cleaner water bodies mean healthier communities, fisheries, and agricultural landscapes.

Finally, the adoption of such systems aligns with global sustainability goals. Many governments are setting targets to reduce agricultural emissions and promote waste-to-resource projects. The fish waste liquid fertilizer plant for drip irrigation system fits perfectly into this framework, making it not only an agricultural innovation but also an environmental policy tool.

The market outlook for fertilizers produced by a fish waste liquid fertilizer plant for drip irrigation system is highly promising.

Consumer demand for organic and eco-friendly agricultural products continues to grow worldwide. Organic certification standards often encourage or mandate the use of natural fertilizers, and fish-based liquid fertilizers have become a preferred option for fruit, vegetable, and vineyard producers. This opens opportunities for producers to sell not only locally but also in high-value export markets.

Governments and international organizations are increasingly supporting sustainable fertilizer initiatives. Subsidies, low-interest loans, and public-private partnerships are being introduced in regions like Southeast Asia, Africa, and South America to encourage waste recycling in agriculture. Facilities that adopt fish waste recycling stand to benefit from such financial and policy incentives.

Another driver is the rapid growth of precision irrigation systems. As drip irrigation expands across Asia and Latin America, the demand for liquid fertilizers compatible with fertigation systems is expected to rise sharply. By positioning fish waste fertilizers within this sector, producers can tap into a rapidly growing market niche.

In addition, large-scale aquaculture and fish processing industries generate massive amounts of by-products each year. Establishing fish waste liquid fertilizer plants for drip irrigation systems near these industries creates a closed-loop business model, ensuring a steady raw material supply and a growing demand for eco-friendly fertilizers.

Q1: What types of fish waste can be used?

Almost all parts of fish—including scales, bones, and viscera—can be processed.

Q2: How does it compare to synthetic fertilizers?

Fish-based fertilizers release nutrients more gradually, improve soil biology, and are safer for the environment.

Q3: Is it suitable for all irrigation systems?

Yes, but drip irrigation provides the most efficient and precise application.

Q4: What is the shelf life of fish waste liquid fertilizer?

With stabilization, it typically lasts 6–12 months.

Q5: Can the fertilizer be used in organic farming?

Yes, fish-based fertilizers meet organic farming standards in many regions.

The fish waste liquid fertilizer plant for drip irrigation system is more than a piece of agricultural infrastructure—it is a model for sustainable development. It addresses waste management challenges in fisheries, supports environmentally responsible farming practices, and provides farmers with affordable, high-quality fertilizers.

By reducing waste disposal problems, preventing water pollution, and lowering greenhouse gas emissions, it delivers substantial environmental benefits. At the same time, it creates strong economic value by opening new markets for organic fertilizers and enabling farmers to boost yields with precision irrigation.

The real-world examples from Portugal’s vineyards and Indonesia’s rice farms demonstrate its versatility: smallholder communities and large-scale agribusinesses alike can benefit. Looking ahead, the integration of fish waste fertilizer production with drip irrigation will become an essential component of circular agriculture, helping to meet global food demand while protecting ecosystems.

In essence, the fish waste liquid fertilizer plant for drip irrigation system is not just a technology but a long-term solution—bridging fisheries and agriculture, profit and sustainability, today’s farming needs and tomorrow’s environmental responsibilities.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.