5t/h liquid fertilizer production line in Israel: a practical project for modern agriculture

Israel is well known for turning limited natural resources into strong agricultural results. In recent years, a fertilizer production line in Israel has become an important topic for growers, investors, and agricultural suppliers who are looking for efficient and sustainable ways to support crop growth. Liquid fertilizer, combined with smart irrigation systems, fits perfectly into this environment.

In this article, we look at why Israel is such a good place for liquid fertilizer, why water–fertilizer integration works so well there, and what equipment is needed to build a 5t/h liquid fertilizer plant. We will also share how we, as LANE, support this kind of project from start to finish.

Israel has a dry climate, limited freshwater resources, and a strong focus on high-efficiency farming. These conditions make liquid fertilizer a natural choice. When we look at a fertilizer production line in Israel, the first thing that stands out is how closely fertilizer use is connected to water management.

Liquid fertilizer is easy to dissolve, easy to control, and easy to deliver directly to crops. Farmers can adjust nutrient ratios quickly based on crop needs, soil conditions, and growth stages. This level of control is very important in a country where every drop of water and every gram of fertilizer matters.

Another reason Israel fits liquid fertilizer well is farm structure. Many farms focus on high-value crops such as vegetables, fruits, and greenhouse products. These crops benefit greatly from precise feeding. A fertilizer production line in Israel supports this by producing stable, uniform liquid fertilizer that works smoothly with modern irrigation systems.

Water–fertilizer integration, often called fertigation, is already widely used in Israel. The country is a global leader in drip irrigation, and liquid fertilizer fits perfectly into this system. Instead of spreading solid fertilizer and watering separately, nutrients are delivered directly with irrigation water.

For a fertilizer production line in Israel, this creates clear advantages. Liquid fertilizer flows easily through pipes and drip lines without blocking them. Nutrients reach plant roots directly, reducing waste and improving absorption. This is especially important in sandy or light soils, which are common in some farming areas.

Water–fertilizer integration also saves labor and time. Farmers do not need extra equipment or extra steps to apply fertilizer. Everything happens in one process. From a production point of view, this increases demand for reliable liquid fertilizer and supports the long-term value of a fertilizer production line in Israel.

Israel places strong importance on environmental protection. Liquid fertilizer supports this goal by reducing runoff and nutrient loss. When fertilizer is applied accurately with water, less nitrogen and other nutrients end up in the soil or groundwater.

At the same time, farmers can lower overall fertilizer use while keeping or even increasing yields. This improves farm income and makes agriculture more sustainable. For investors and operators, building a fertilizer production line in Israel is not only about meeting current demand but also about supporting long-term agricultural policies and market trends.

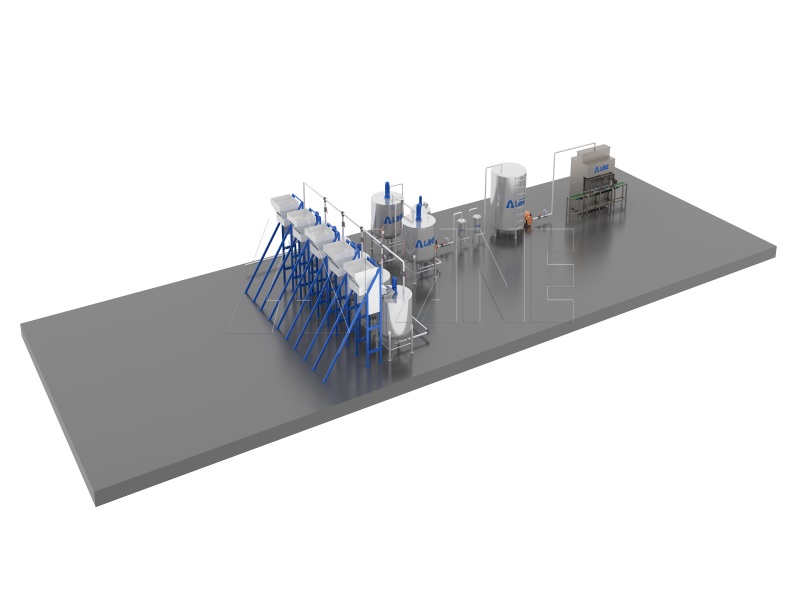

Building a 5t/h liquid fertilizer factory requires a clear and practical equipment setup. For a fertilizer production line in Israel, reliability and easy operation are especially important, because many plants run continuously during peak farming seasons.

The core equipment usually includes:

Raw material storage and feeding systems

Liquid raw materials and water need safe storage tanks. Accurate feeding pumps ensure correct ratios and stable quality.

Dissolving and mixing tanks

Solid materials such as trace elements or additives must be fully dissolved. Mixing tanks with proper agitation help achieve uniform fertilizer solutions.

Reaction and blending systems

Some liquid fertilizers require controlled reactions. Blending systems allow flexible formulas to meet different crop needs, which is a key feature for a fertilizer production line in Israel.

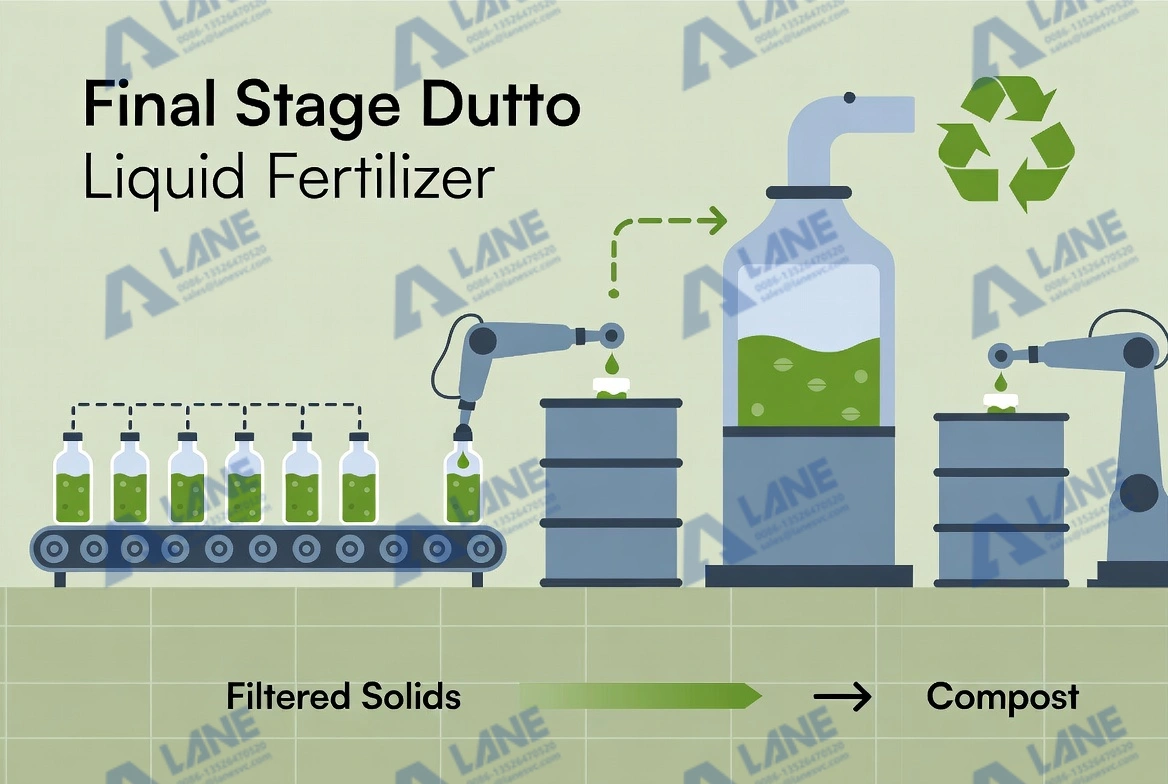

Filtration and impurity removal

Filtration protects irrigation systems from blockage. Clean fertilizer is essential for drip irrigation.

Filling and packaging equipment

Finished products can be filled into tanks, barrels, or containers based on market demand. Automation improves efficiency and reduces labor.

Control system

A simple and reliable control system helps operators manage production easily and ensures stable output at 5t/h capacity.

All these units work together to form a smooth, efficient fertilizer production line in Israel that can adapt to different formulas and market needs.

Project-oriented thinking for Israel’s market

A 5t/h liquid fertilizer plant is not oversized or too small for Israel. It fits well with regional distribution needs and allows flexible production planning. Operators can produce different products in batches, respond quickly to seasonal demand, and serve both local farms and export markets.

From a project point of view, planning a fertilizer production line in Israel also means thinking about installation, training, and after-sales support. Equipment must be easy to maintain, and spare parts should be available without long delays.

As LANE, we have been working in the fertilizer machinery field for more than 20 years. When we support a fertilizer production line in Israel, we focus on practical solutions rather than complex theory.

We have our own professional engineering team, and we design and manufacture equipment based on real customer needs. Whether it is formula flexibility, plant layout, or automation level, we customize the production line to fit local conditions and customer goals.

We also provide full production line installation and commissioning. Our service does not stop after delivery. We offer one-stop support, including maintenance guidance, troubleshooting, and future upgrades. This helps customers keep their fertilizer production line in Israel running smoothly and efficiently over the long term.

All our equipment meets international quality standards such as ISO9001 and CE. This gives customers confidence in safety, reliability, and long service life.

Liquid fertilizer and water–fertilizer integration will continue to play a key role in Israel’s agriculture. With strong demand for efficient and sustainable farming inputs, a well-designed fertilizer production line in Israel offers both economic and environmental value.

By choosing the right equipment, planning carefully, and working with an experienced partner, investors and producers can build a stable 5t/h liquid fertilizer plant that meets today’s needs and tomorrow’s challenges. At LANE, we are ready to support these projects with professional design, reliable equipment, and long-term service, helping modern agriculture grow in a smarter and more efficient way.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.