Liquid Fertilizer from Digestate Plant: A Complete Guide to Production and Benefits

The biogas industry is celebrated as an eco-friendly industry for their renewable energy. But the true value of a circular economy lies in the full usage of all outputs. The digestate, a by-product of the biogas industry, is often regarded as a secondary by-product. This secondary by-product is a primary resource for sustainable agriculture, thanks to liquid fertilizer from digestate plant.

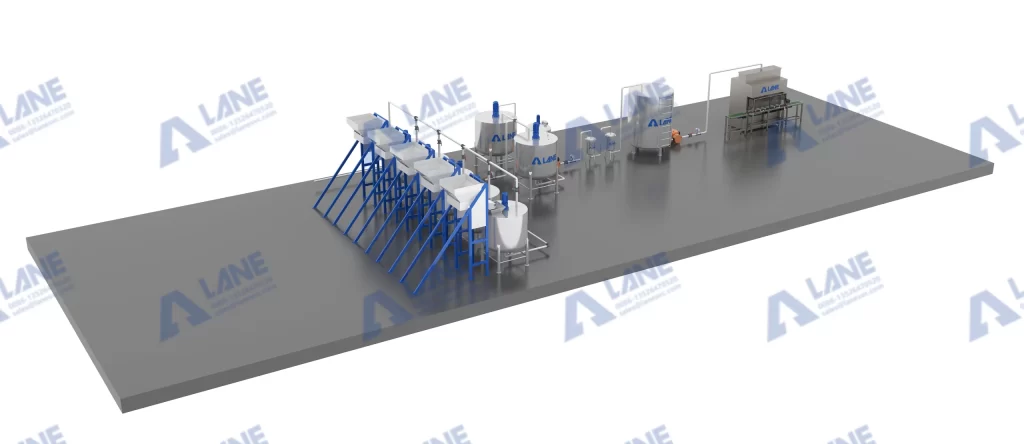

Transforming this digestate into a refined, nutrient-rich liquid fertilizer is not just an add-on to the biogas farm, it’s a huge profit opportunity. Henan LANE Heavy Industry Machinery Technology Co., Ltd., a pioneer in agricultural and environmental equipment, has designed a production line that scales this transformation, equipping businesses with machinery that turns messy digestate into consistent, high-performance liquid fertilizer.

This article explores the complete journey from raw digestate to a high-value fertilizer from a digestate plant.

Raw digestate is a nutrient-dense slurry which contains valuable nitrogen (N), phosphorus (P), potassium (K), and organic matter. It cannot be used directly as it has odor, potential pathogen content, and inconsistent nutrient profiles. It must first be processed before you can call it fertilizer.

The goal is to separate the solid fraction from the liquid, which will create a stable, homogenous, and easy-to-apply liquid fertilizer from the digestate plant which farmers love to use.

To create a consistent high-quality product, you need a production line that can do precise mechanical separation and refinement. Partnering with LANE Machinery ensures each step is optimized for maximum nutrient recovery and operational efficiency.

Pre-Separation and Storage: This process begins with homogenizing the raw digestate in a fermentation tank. Consistent feedstock is key to stable separation results. The fermentation process takes 10-15 days.

Core Mechanical Separation: In this process, liquid is separated from the solids. LANE screw press or liquid-solid separator is used in this process. This technology applies immense mechanical force to cleanly split the digestate. The solid fraction, which is rich in fibers and organic matter, is captured for use as compost or bedding.

Liquid Refinement: The separated liquid is then sent to the main mixing tank where it is mixed with different batches of solution or valuable nutrients are added to refine the formula. LANE mixing tank is used in this stage for homogeneous mixing.

After the main mixing, the liquid is sent to LANE additive mixing tank. Various additives are used to increase the shelf life of the liquid fertilizer.

The separated liquid may still contain fine suspended particles. LANE dual filter is used to refine the high-quality liquid fertilizer and remove any impurities it might have. This makes the liquid look premium and creates a clear product that won’t clog irrigation or spraying equipment.

Storage & Application: The final liquid fertilizer is stored in a LANE storage tank. This tank has aeration control; this makes sure that liquid doesn’t settle in the storage and form crystals. The final product is perfectly suited for modern application methods like tanker spreading, fertigation, or direct injection into soil, maximizing nutrient uptake by crops.

It produces a refined fertilizer from digestate plant. This creates a powerful win-win-win scenario for operators, farmers, and the environment.

For the Biogas Plant Operator, this production line brings:

New Revenue Stream: This production line transforms a burden into a profitable product. Liquid fertilizer has more value than raw digestate.

Eliminates Disposal Costs: This eliminates the cost of disposal. You have to pay to dispose of the raw digestate. This cost can be used to make liquid fertilizer which brings profit.

Future-Proofs Operations: This production line meets the regulatory requirements for nutrient management and product quality.

Enhances Public Image: This is a huge marketing tool for your company. It demonstrates a full commitment to the circular economy and sustainable resource recovery.

Superior Crop Nutrition: For farmers, this refined fertilizer from digestate plant provides fast-absorbing, balanced nutrients, which are ideal for plant growth, often with a complementary organic carbon content.

Soil Health: This fertilizer from digestate plant replenishes organic matter and improves soil structure and water retention without the harsh effects of some synthetic fertilizers.

Cost-Effective: The fertilizer is an economical solution to those high-priced synthetic fertilizers. It offers a potent, locally sourced alternative to increasingly expensive mineral fertilizers.

Precision Application: This liquid fertilizer from digestate plant allows for accurate, variable-rate application, which minimizes waste and optimizes nutrient use efficiency.

For the Environment:

As sustainable agriculture gains momentum, fertilizer from digestate plant stands as a model of resource recycling. It represents the intelligent completion of the organic waste cycle. With partners like LANE Machinery providing the essential technological backbone, this transition is both achievable and economically beneficial.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.