A Step-by-Step Guide to EU Standard Liquid Fertilizer Production Line

The European Union (EU) has established standards for liquid fertilizer production which focus on product safety and environmental protection. Most importantly, the EU Fertilising Products Regulation (FPR) 2019/1009 was created to safeguard agricultural sustainability and human health.

Producing liquid fertilizers is a commitment to the highest level of quality, safety, and environmental stewardship. EU standards set a framework for precise nutrient declarations, stringent contaminant limits, and full traceability. To meet this standard, an EU standard liquid fertilizer production line must be engineered to deliver accuracy, hygiene, and control from the raw material to the final packaged fertilizer.

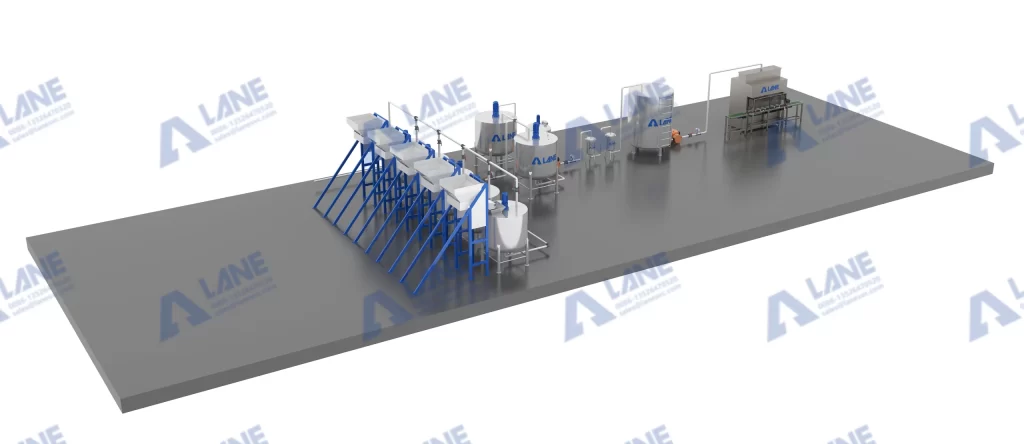

LANE Heavy Industry, a leading provider of agricultural machinery, offers turnkey EU standard liquid fertilizer production lines tailored to these demands. This guide walks through the essential steps of this process.

The first step of the journey begins before the production even starts: the sourcing of high-quality raw materials. The raw materials must be approved by the EU. They can be mineral salts, acids, chelating agents, or organic concentrates. Receiving and sorting these raw materials are the first step of the production.

For an EU standard liquid fertilizer production line, this requires dedicated lined or stainless-steel storage tanks to prevent contamination. LANE Heavy Industry designs and manufactures corrosion-resistant storage solutions.

The second step of the production line is Weighing & Batching. In this stage, raw materials are transferred from storage to the batching area. Under EU standards, the exact nutritional content declared on the label must match the final product.

A LANE engineered EU Standard Liquid Fertilizer Production line contains a dynamic batching and dosing system that has automated weight scales and flow meters. An operator can manage this via a central PLC (Programmable Logic Controller). This system draws a precise amount of raw material as inputted by the operator. This ensures formula integrity and the highest level of control. This helps create a digital batch record, essential for EU compliance and quality audits.

After raw materials are batched, they are sent to the raw material mixing tank. This is where the actual chemical process begins. In the raw material reactor, ingredients are dissolved with water or other liquid materials under specific conditions of temperature, pressure, and agitation to form stable, homogeneous solutions or suspensions.

After that, they are sent to the main mixing tank where different batches of raw material solution or suspensions are mixed together to form the final formula. After that, they are sent to the additive mixing tank to be mixed with chelation agents and other micronutrients to finish the final formula.

LANE Heavy Industry’s corrosion-resistant reactors are the workhorses of this stage. They feature jacketed walls for precise temperature control and high-shear agitators designed by LANE’s engineers to ensure perfect mixing. The reaction parameters are continuously monitored and logged. This guarantees that each batch is synthesized identically.

The final solution must go through filtration as it may contain undissolved particles or by-products that must be removed to ensure clarity and stability. It makes the liquid fertilizer look more premium. It also makes sure that undissolved particles don’t cause clogging in the end-user’s application equipment.

The conditioned liquid is passed through filters such as dual filters or cartridge filters manufactured by LANE. These filters achieve crystal clarity which makes the liquid fertilizer look premium.

The final steps of the production line focus on packaging the certified liquid fertilizer. The finished liquid fertilizers are sent to the storage tank for stabilization. From there, they are sent to the fully automated filling machine via pipes. These fillers, integrated into the LANE production line, accurately dispense the product into bottles, canisters, or IBCs without spillage and with minimal exposure to air.

Samples from every batch are automatically sent to the testing area where they are tested against the EU-declared parameters like nutrient content, pH, density, heavy metal limits, and stability.

Only after passing all QC checks are they approved for warehousing and shipment.

Producing EU standard liquid fertilizer requires a systematic process, and LANE Heavy Industry’s EU standard liquid fertilizer production line stands out for its integration of precision machinery, intelligent control, and compliance-oriented design. It transforms raw materials into a guaranteed, consistent product that meets the highest regulatory benchmarks.

Q1: Why are EU standards so important for liquid fertilizer production?

A: EU standards, particularly the Fertilising Products Regulation (FPR) 2019/1009, are crucial because they ensure product safety, environmental protection, and agricultural sustainability. They establish a strict framework for precise nutrient content, impose stringent limits on contaminants like heavy metals, and mandate full traceability. Complying with these standards is not just a legal requirement for selling in the EU market; it is a mark of high quality, safety, and reliability that builds trust with farmers and distributors.

Q2: What is the single most important feature of an EU standard liquid fertilizer production line?

A: While it integrates many critical features, the cornerstone is precision and control at every stage. An EU standard liquid fertilizer production line must guarantee that the final product’s composition exactly matches its declared formula. This requires precise weighing, batching, reaction control, and comprehensive quality checks. LANE Heavy Industry’s lines are engineered with this principle in mind, using automated PLC systems to eliminate human error and ensure batch-to-batch consistency.

Q3: How does LANE’s batching system ensure formula accuracy?

A: LANE’s EU standard liquid fertilizer production line utilizes a dynamic batching and dosing system with automated weight scales and flow meters. Operated via a central PLC, this system draws precisely calculated amounts of each raw material. This high level of automation ensures the exact nutritional content is achieved every time, which is fundamental for EU label compliance. It also automatically generates a digital batch record for full traceability and audits.

Q4: The article mentions multiple mixing tanks (raw material, main, additive). Why is this multi-stage process necessary?

A: The multi-stage reaction and synthesis process is essential for creating a stable, homogeneous, and effective final product. Different raw materials may require specific conditions (temperature, agitation) to dissolve or react properly in the initial tanks. Combining these pre-mixed solutions in the main tank allows for controlled final formulation. A dedicated additive tank ensures delicate components like chelating agents or micronutrients are integrated without degradation. This meticulous approach, central to LANE’s design, guarantees the chemical stability and efficacy required by EU standards.

Q5: What is the purpose of the filtration stage, beyond just making the fertilizer look “premium”?

A: While crystal clarity enhances market appeal, filtration in an EU standard liquid fertilizer production line serves vital technical functions. It removes undissolved particles and by-products to prevent sedimentation, which ensures the product remains stable and homogeneous throughout its shelf life. Most importantly, it prevents clogging in modern, precise agricultural application equipment like fertigation and foliar spray systems, protecting the farmer’s investment and ensuring accurate delivery.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.