What equipment is used in water-soluble fertilizer production?

When people first ask equipment is used in water-soluble fertilizer production, they are usually surprised by how systematic and well-organized the whole process is. Making water-soluble fertilizer is not just about mixing powders together. It involves a series of specialized machines, each playing a clear role, working step by step like a well-trained team. From feeding raw materials to final packaging, every piece of equipment affects product quality, efficiency, and cost. Understanding equipment is used in water-soluble fertilizer production is the first step for anyone planning to set up a production line.

In this article, I’ll walk you through the main equipment used in water-soluble fertilizer production, explain how each one works, and share why these machines matter so much in real production lines. I’ll also show how equipment is used in water-soluble fertilizer production ensures efficiency, quality, and safety.

The feeding system is where production officially begins. Its main job is to deliver raw materials—such as urea, potassium sulfate, trace elements, and additives—into the next process smoothly and accurately. Knowing equipment is used in water-soluble fertilizer production helps you appreciate why a reliable feeding system matters so much.

Most feeding systems use screw feeders or belt feeders. These machines control the feeding speed, making sure materials enter the system evenly instead of all at once. This helps avoid blockages and ensures consistent product quality.

Performance & Advantages:

A reliable feeding system sets the tone for the entire production line.

Not all raw materials arrive in perfect powder form. That’s why a crushing system is needed. Crushers break down large particles into fine, uniform sizes suitable for mixing. Understanding equipment is used in water-soluble fertilizer production helps explain why crushing is so essential.

Hammer crushers and chain crushers are commonly used. They work by high-speed rotation that impacts and grinds materials until they reach the required fineness.

Performance & Advantages:

Without proper crushing, even the best mixer can’t do its job well.

Dust may seem like a small issue, but in fertilizer production, it’s a big deal. Fine powder dust can pollute the environment, harm workers, and cause material loss. Equipment is used in water-soluble fertilizer production includes dust collection for safety and efficiency.

Dust collection systems use fans and filters to capture airborne particles during crushing and mixing. Collected dust is often recycled back into production.

Performance & Advantages:

A good dust removal system makes production more professional and sustainable.

Before final mixing, many production lines include a pre-mixing system. This step combines small-quantity ingredients like trace elements and micronutrients.

The goal is simple: make sure these minor components are evenly distributed before entering the main mixer. This step is part of understanding how equipment is used in water-soluble fertilizer production ensures uniformity.

Performance & Advantages:

Think of it as warming up before the main event.

The stainless-steel mixer is the heart of water-soluble fertilizer production. Ribbon mixers or double-shaft mixers are commonly used. Knowing equipment is used in water-soluble fertilizer production highlights why a high-quality mixer is crucial.

They rotate materials continuously, ensuring every ingredient blends evenly. This step directly affects fertilizer quality and customer satisfaction.

Performance & Advantages:

Good mixing means better solubility and more reliable nutrient delivery.

After mixing, the fertilizer needs to be packed and sealed. Sealing machines close bags tightly to protect products from moisture and contamination. This is another example of how equipment is used in water-soluble fertilizer production ensures quality throughout the process.

Automatic sealing machines work fast and reduce manual labor, making them ideal for large-scale production.

Performance & Advantages:

Proper sealing helps maintain fertilizer quality during storage and transport.

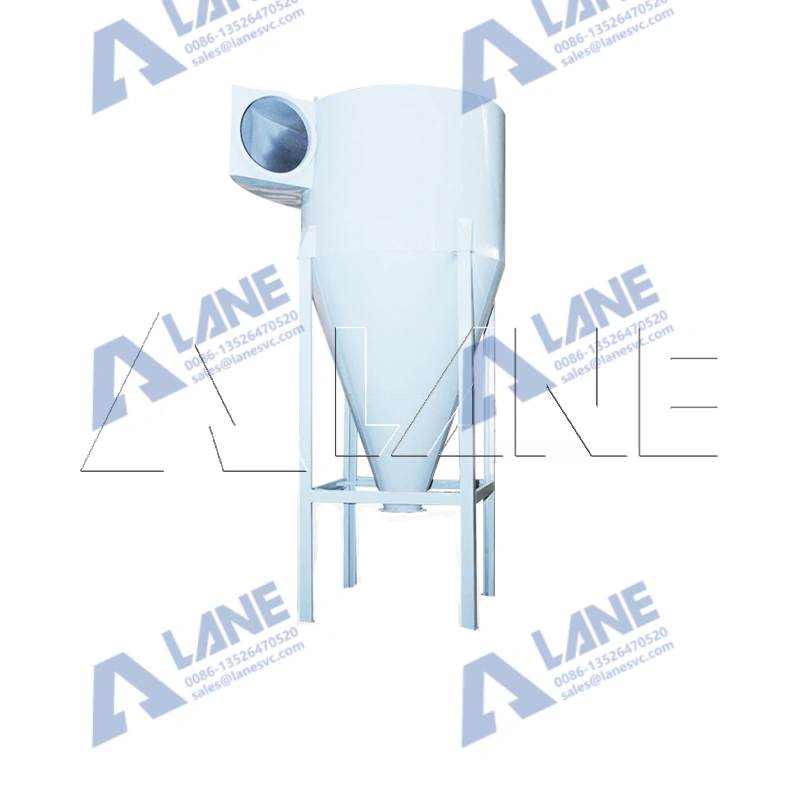

Storage silos are used to temporarily store finished fertilizer or raw materials. They help balance production flow and prevent bottlenecks.

Most silos are designed with moisture-proof structures to protect water-soluble fertilizer from humidity.

Performance & Advantages:

A well-designed silo keeps everything running smoothly.

Conveyor belts link all machines together. They move materials automatically between processes, reducing manual handling.

Different conveyor types—belt conveyors, screw conveyors, bucket elevators—are selected based on material properties. Understanding equipment is used in water-soluble fertilizer production includes knowing how materials are moved efficiently.

Performance & Advantages:

Conveyors are like the roads connecting every part of the factory.

The central control system monitors and controls the entire production line. Operators can adjust parameters, check machine status, and spot problems early. Equipment is used in water-soluble fertilizer production is only as effective as the control system managing it.

Modern systems use PLC and touch screens for easy operation.

Performance & Advantages:

With smart control, production becomes more stable and efficient.

At LANE, we don’t just talk about equipment—we work with it every day. Our company has been focusing on fertilizer machinery manufacturing for over 20 years, and during that time, we’ve learned what really works in real factories.

We design complete water-soluble fertilizer production lines based on customer needs, not fixed templates. Our engineering team handles everything from equipment design to installation. We follow ISO9001 and CE standards, which helps us ensure stable quality and long-term performance.

More importantly, we stay with our customers after delivery. Whether it’s maintenance, upgrades, or troubleshooting, we believe good equipment should come with reliable support—and that’s exactly what we aim to provide.

Understanding what equipment is used in water-soluble fertilizer production helps explain why modern fertilizer factories are efficient, clean, and precise. Every machine—from feeding systems to central control—plays a role in producing high-quality fertilizer that dissolves quickly and works effectively in the field.

When all equipment works together properly, the result is not just fertilizer, but trust from farmers and customers alike.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.