The Complete Process: How an Environmentally Friendly Liquid Fertilizer Production Line Works

In the world of modern agriculture, agribusinesses and consumers both demand sustainable farming practices. Consumers demand that farmers use environmentally friendly fertilizers. The development of an environmentally friendly liquid fertilizer production line has become a cornerstone of eco-conscious farming. It provides farmers and agricultural businesses with an efficient way to produce organic fertilizers that enhance soil health while minimizing environmental harm.

This article explores the production process of LANE Heavy Industry’s environmentally friendly liquid fertilizer production line.

An environmentally friendly liquid fertilizer production line is a system designed to produce liquid fertilizers from organic or non-toxic materials. LANE’s production line uses advanced machinery to automate the process. This reduces manual labor, minimizes waste, and ensures a consistent and high-quality product. By using eco-friendly raw materials such as plant extracts, manure, and bio-based nutrients, our production lines help produce fertilizers that are safe for both the environment and crops.

An environmentally friendly liquid fertilizer production line offers several key advantages to the producer, including:

LANE Heavy Industry is a leader in the design and manufacturing of advanced machinery for fertilizer production. Our environmentally friendly liquid fertilizer production line is known for its efficiency, sustainability, and minimal environmental impact.

4.1. Key Features of LANE’s Production Line

4.2. Energy Efficiency and Sustainability

LANE’s environmentally friendly liquid fertilizer production line has the advantage of an energy-efficient design. Our system incorporates energy-saving technologies like automated temperature control, low-energy mixing, and waste heat recovery. These innovations help reduce overall energy consumption, making the entire production process more cost-effective and environmentally sustainable.

The process of creating environmentally friendly liquid fertilizer involves several steps. From raw material sourcing to packaging, LANE’s production line follows a logical flow.

5.1. Sourcing Raw Materials

The first step in the production process is sourcing high-quality, eco-friendly raw materials. These materials include organic compost, animal manure, plant-based extracts, fish emulsion, and other organic by-products.

5.2. Preparation and Mixing of Materials

Once the raw materials are sourced, they are prepared and mixed in large tanks. LANE’s automated mixing systems use precise controls to ensure that nutrients are evenly distributed throughout the mixture. This creates a balanced fertilizer that is rich in essential nutrients like nitrogen, phosphorus, and potassium.

5.3. Fermentation and Nutrient Release

The mixed raw materials are then sent to the fermentation tank. In this process, beneficial microorganisms break down organic matter, releasing vital nutrients. This biological process ensures that the liquid fertilizer is rich in organic compounds. The whole process is carefully controlled by PLC, promoting the long-term health of the soil and supporting microbial activity.

5.4. Filtration and Quality Control

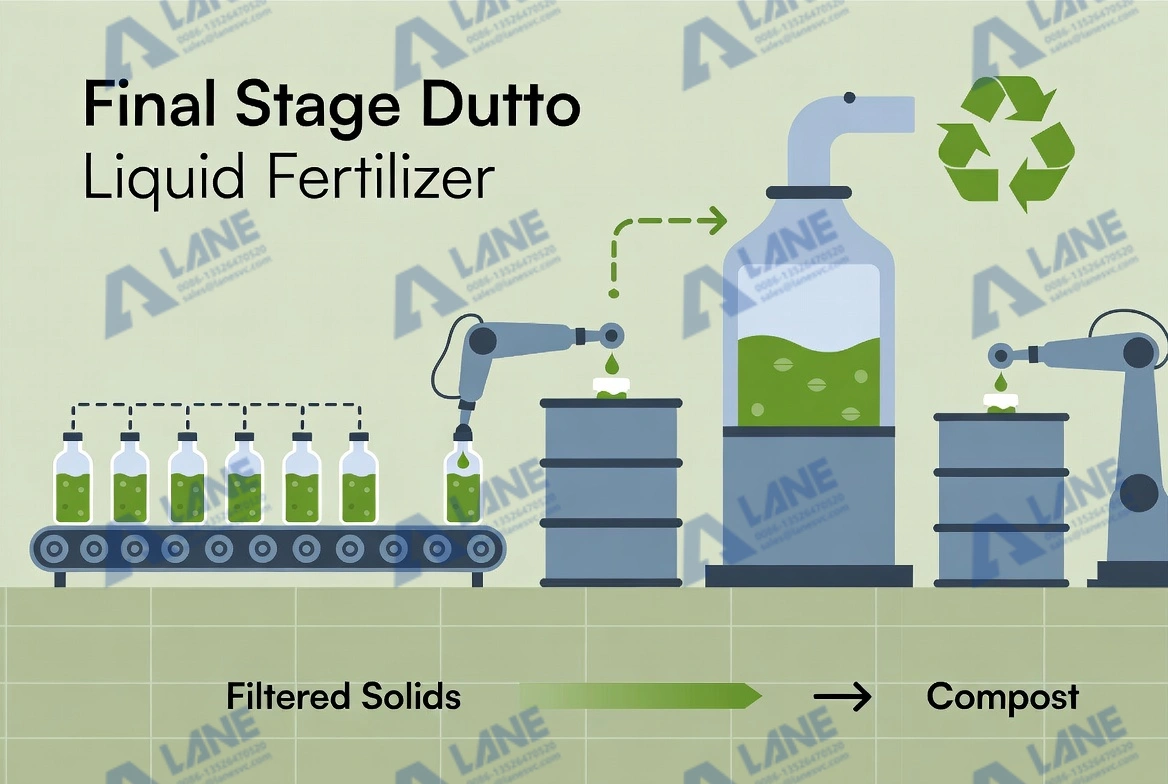

After fermentation, the liquid fertilizer goes through a filtration process to remove any solids or contaminants. LANE uses a dual-stage filtration process in this stage. It effectively removes solids from the liquid, ensuring that only clean, nutrient-rich liquid enters the final product. Quality control measures are implemented at each stage to ensure consistency and purity.

5.5. Packaging and Distribution

The final stage is packaging. LANE’s automated filling machines carefully package the liquid fertilizer into bottles, drums, or bulk containers, depending on the customer’s needs. Once the product is sealed and labeled, it is ready for distribution to agricultural businesses or farmers.

LANE’s environmentally friendly liquid fertilizer production line is designed with control measures to reduce environmental impact.

Q1: What are the main advantages of using an environmentally friendly liquid fertilizer?

A1: Environmentally friendly liquid fertilizers improve soil health, reduce environmental pollution, enhance nutrient absorption, and support sustainable farming practices.

Q2: Can the production line be scaled for large operations?

A2: Yes, LANE’s liquid fertilizer production line is modular and scalable, making it suitable for both small-scale and large-scale operations.

Q3: How does LANE’s system improve energy efficiency?

A3: LANE’s system incorporates advanced energy-saving technologies, including heat recovery systems and low-energy mixing processes, which reduce overall energy consumption during production.

Q4: Is the production line easy to operate?

A4: Yes, the system is highly automated, reducing the need for manual intervention. LANE also provides training and technical support to ensure smooth operation.

Q5: How do I know if the liquid fertilizer meets quality standards?

A5: LANE’s production line incorporates rigorous quality control checks at each stage of the production process, including filtration and nutrient testing, to ensure the final product meets industry standards.

LANE Heavy Industry’s environmentally friendly liquid fertilizer production line represents a sustainable revolution in agriculture, turning waste into wealth while protecting the environment. Implementing this production line is a significant step forward in sustainable agricultural practices. By providing an efficient, cost-effective, and eco-friendly solution for fertilizer production, this system helps agricultural businesses reduce their environmental impact while meeting the growing demand for organic fertilizers.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.