Guide to Investing in an Energy-saving Liquid Fertilizer Production Line

The modern agricultural sector demands higher productivity, soil health preservation, and reduced environmental impact. It is expanding the market for organic and liquid fertilizers. Concurrently, rising global energy costs make operational efficiency non-negotiable. An energy-saving liquid fertilizer production line directly addresses these challenges. It allows producers to convert organic waste streams like agricultural residues, food waste, or animal manure into high-value liquid fertilizer. This turns a disposal problem into a revenue stream.

Traditional liquid fertilizer production lines are known for wasting energy and having high operating costs. An Energy-saving Liquid Fertilizer Production Line minimizes energy consumption while ensuring high-quality liquid fertilizer output, aligning with modern agricultural development trends and policy. LANE Heavy Industry, a leading manufacturer of high-performance Energy-saving Liquid Fertilizer Production Lines, provides comprehensive solutions to help investors achieve long-term profitability.

A modern energy-saving liquid fertilizer production line implements several key technologies to minimize power and thermal energy use:

LANE Heavy Industry provides customized turnkey solutions. We approach each project with a collaborative design process. We don’t believe one-size-fits-all is suitable for modern farming.

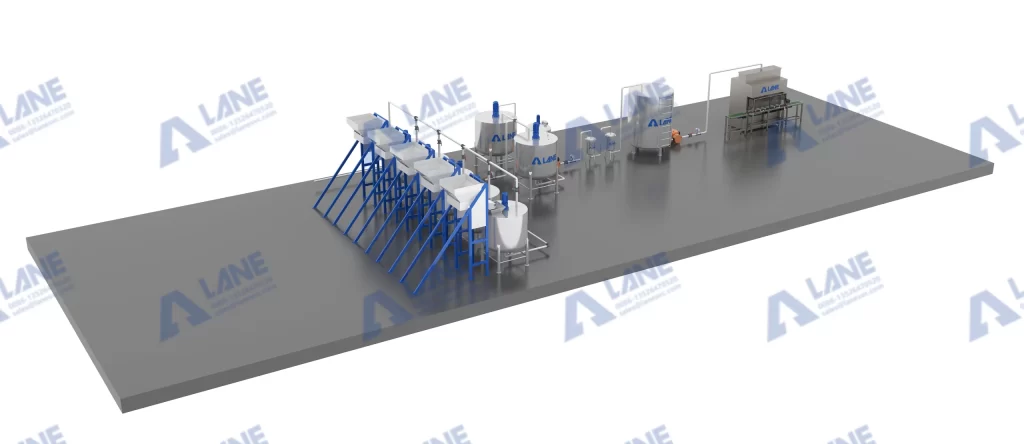

LANE’s engineers design complete energy-saving liquid fertilizer production lines featuring a crusher, temperature-controlled fermentation tanks, enzymatic digestion tanks, blending systems, and automated filling. All the machines are made with industrial-grade stainless steel components. The machines are easy to maintain and ensure long-term, efficient operation.

LANE has the capability to handle diverse raw materials and deliver a line with a capacity of 10 or more tons per day. We oversee overseas installation and operator training.

| Feature | LANE Heavy Industry Custom Line | Industry High-Capacity Example |

| Customization | Fully customized based on raw material (e.g., soybean dregs, seaweed kelp) | Designed for specific feedstock (biogas digestate) |

| Key Energy-Saving Tech | Insulated fermentation, automated controls | Triple-effect evaporator, vapor recompression (TVR) |

| Output Capacity | 10tons/day to 20 tons/hour(configurable) | 50,000 tons/year |

| Core Advantage | Turnkey solution with full support | Large-scale industrial efficiency & proven ROI |

energy-saving liquid fertilizer production line requires a detailed analysis and considerable investment. Beyond the equipment, there are many other costs like site preparation, raw material sourcing, and utility access. Financially, an industrial grade custom model is essential for premium grade liquid fertilizers. The robust production line includes projecting capital expenditures (machinery, installation), operating costs (raw materials, utilities, labor), and revenue.

A well-designed energy-saving liquid fertilizer production line impacts operating margin by reducing power costs. for example, an optimized urea liquid fertilizer system can use 80% less heating energy than traditional methods. Furthermore, using organic waste as raw material is very cheap can lead to very low operating cost which improves profitability.

Table: Overview of LANE Heavy Industry Production Line Models (Examples)

| Model Type | Key Raw Material | Capacity Range | Core Energy-Saving Feature |

| Organic Liquid Fertilizer Line | Food waste, manure | 1-30 T/H | Automated PLC control for optimized processes |

| Slow-Release Fertilizer Line | Composite materials | 2-15 T/H | High granulation rate (95%) reducing material/energy waste |

A successful project follows a phased approach:

Q1: What raw materials can be processed with LANE’s energy-saving liquid fertilizer production line?

A: LANE’s lines are highly adaptable. They can be customized to process a wide variety of organic materials, including soybean dregs, food waste, animal manure, and other agricultural or industrial organic residues.

Q2: How significant are the energy savings with this type of production line?

A: Savings are substantial and multi-faceted. They arise from efficient motor systems, reduced thermal energy needs through technologies like multi-effect evaporation, and smart automation that eliminates unnecessary equipment runtimes. Specific technologies can reduce energy consumption for certain processes by 60-80%.

Q3: What kind of after-sales support can I expect?

A: Reputable manufacturers like LANE offer comprehensive support. This often includes a warranty (e.g., 5 years on core components), provision of operation manuals, remote technical assistance, and the availability of engineers for on-site troubleshooting and maintenance support.

Q4: Is there a minimum viable scale for such an investment to be profitable?

A: Profitability depends on your local market, feedstock costs, and energy prices. However, the scalable and modular nature of modern energy-saving liquid fertilizer production lines allows for configurations suitable for medium-sized operations. Detailed financial modeling during the planning phase is critical to determine the viable scale for your specific context.

Q5: Can the production line be upgraded or expanded in the future?

A: Yes, a key advantage of a modular energy-saving liquid fertilizer production line design is scalability. You can start with a core system and later add modules for increased capacity, additional processing stages (like further concentration or different blending), or enhanced automation as your business grows.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.