Customized Liquid Fertilizer Production Line: Design, Capacity & Turnkey Solutions

Liquid fertilizer is known for its precision and fast nutrient absorption quality. It is perfect for modern precision agriculture. Generic, one-size-fits-all fertilizers are increasingly being replaced by specialized formulations. But to create specialized formulation you will need a customized liquid fertilizer production line. A customized liquid fertilizer production line delivers precise nutrient ratios, enhanced bioavailability, and reduced environmental impact. In recent years it has become the core choice for farms, fertilizer factories, and agricultural enterprises.

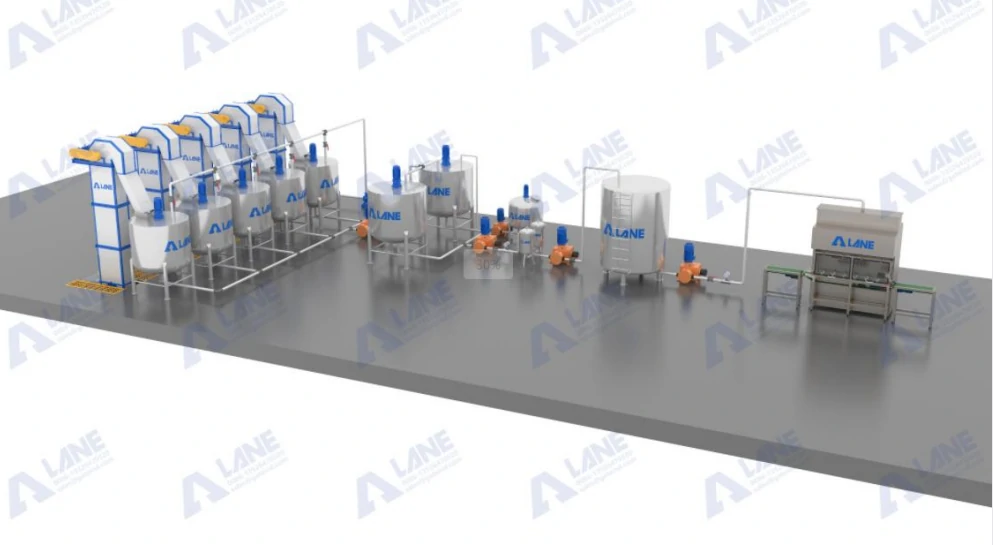

A customized liquid fertilizer production line can produce liquid fertilizer from diverse raw materials. Unlike standard, rigid systems, a tailored line transforms a production facility from a static blender into a dynamic formulation hub. LANE Heavy Industry, with its engineering expertise, stands at the forefront of designing and manufacturing this purpose-built solution.

The core of a successful customized liquid fertilizer production line lies in its design and engineering philosophy. LANE Heavy Industry approaches every project as a special case. Our partnership is centered on a modular design principle.

A LANE customized liquid fertilizer production line is built around intelligent mixing systems. These mixers are high-shear reactors that ensure homogeneous blending and rapid dissolution of raw materials. From this core, the line is configured with modular components based on the client’s target products:

Our modular approach ensures the customized liquid fertilizer production line is precisely engineered. It provides the exact functionality required for products with the flexibility to adapt to tomorrow’s innovations.

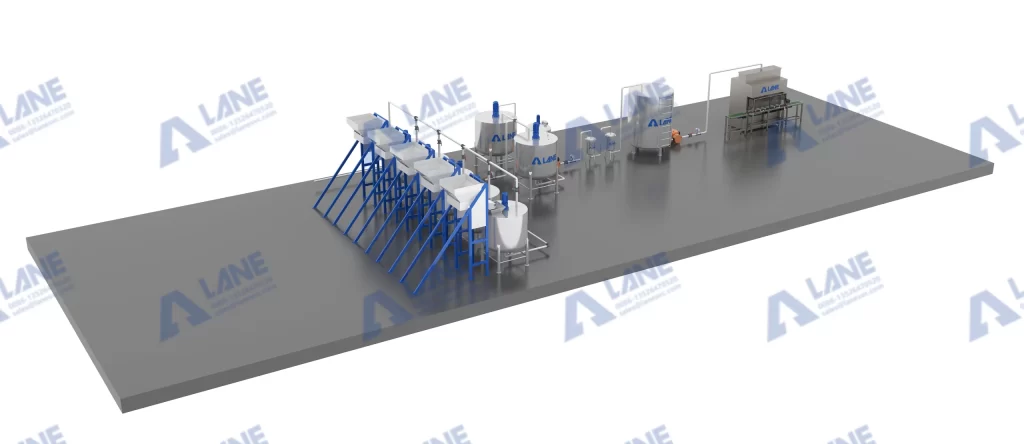

Capacity is one of the primary drivers in the design of a customized liquid fertilizer production line. LANE Heavy Industry delivers designs that can fit according to customer capacity spectrum, proving that customization is not exclusive to large-scale operations.

Regardless of the scale, a well-designed customized liquid fertilizer production line from LANE is engineered for scalable growth. We provide manufacturers with clear pathways for future capacity expansion.

Investing in a customized liquid fertilizer production line is a significant project. Its influence extends beyond machinery. LANE Heavy Industry distinguishes itself from other companies by offering true turnkey solutions. We manage the project from inception to operational handover.

A LANE turnkey project typically includes:

Our approach de-risks the project for the client and it ensures a single point of accountability and a smoother, faster path to production and profitability.

In a market defined by specific nutrient demands and efficiency standards, the ability to produce tailored fertilizer formulations is a powerful competitive edge. LANE Heavy Industry’s customized liquid fertilizer production line stands out in the industry with tailored design, flexible capacity, and comprehensive turnkey solutions. We help customers with pain points such as raw material adaptation, capacity mismatch, and high operation costs by integrating advanced technology and intimate service.

Q1: How does the customization process with LANE Heavy Industry begin?

The process starts with a detailed consultation. LANE engineers will discuss your target product portfolio (formulations, physical characteristics), raw materials, desired annual/batch capacity, site constraints, and automation goals. This information forms the basis for the preliminary design and proposal.

Q2: Is a customized line more expensive than a standard off-the-shelf system?

While the initial investment may be different, a customized liquid fertilizer production line is optimized for your specific operations, minimizing waste, reducing labor costs, and maximizing output efficiency. This leads to a faster return on investment (ROI) and lower cost-per-ton in the long run compared to a standard system that may require compromises or inefficient workarounds.

Q3: Can the production line be expanded or modified in the future?

Absolutely. The modular design philosophy central to LANE’s approach means that capacity can be increased (e.g., with larger or additional mixing tanks), and new functionality (e.g., an additional ingredient dosing station) can typically be integrated with minimal disruption to the existing line.

Q4: What level of automation can be included?

Automation can range from basic semi-automatic control of mixing cycles to a fully automated plant with recipe management, automated raw material dosing via load cells or flow meters, CIP (Clean-in-Place) systems, and full production data tracking and reporting. The level is tailored to your budget and operational requirements.

Q5: Does LANE provide support for formula development and troubleshooting?

While core R&D is typically conducted by the client, LANE’s extensive process engineering experience allows them to provide crucial guidance on equipment suitability for different formulations (e.g., suspension stability, corrosion prevention) and offer troubleshooting support during commissioning and operation to ensure the line performs as intended with your specific recipes.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.