Compost Tea Liquid Fertilizer Production Line – Advanced Brewing Solutions for Sustainable Farming

In recent years, sustainable agriculture has evolved from a niche concept to a global focus. Farmers, horticulturists, and greenhouse growers are seeking alternatives to synthetic fertilizers to enhance soil fertility, boost crop resilience, and reduce reliance on chemicals. One solution that has gained significant attention is compost tea – a nutrient-rich liquid fertilizer brewed from mature compost and teeming with beneficial microorganisms.

Although small-scale brewing methods have existed for decades, they cannot meet the demands of commercial farms or fertilizer manufacturers for large quantities of stable, high-quality products. Advanced compost tea liquid fertilizer production lines have emerged as a result. These specialized systems ensure controlled brewing conditions, optimized microbial growth, and efficient large-scale production. As a global leader in fertilizer production technology, LANE designs and manufactures such production lines to help agricultural enterprises convert organic waste into valuable “liquid gold” for crops.

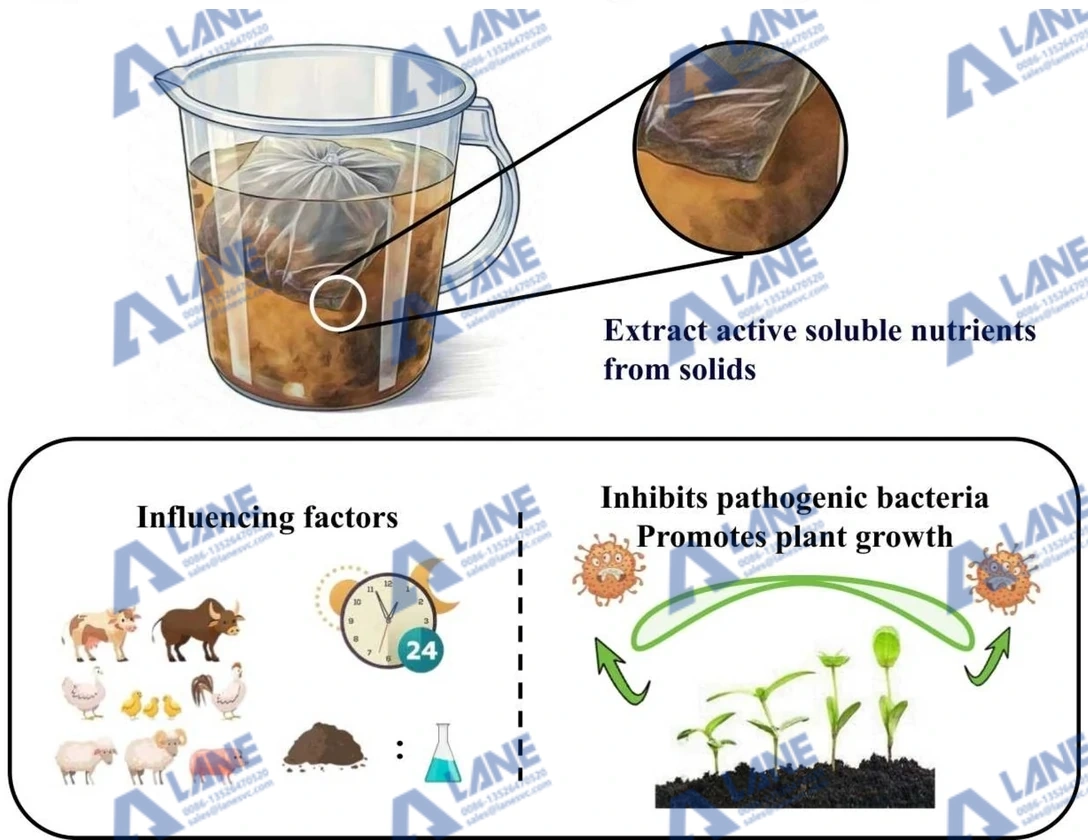

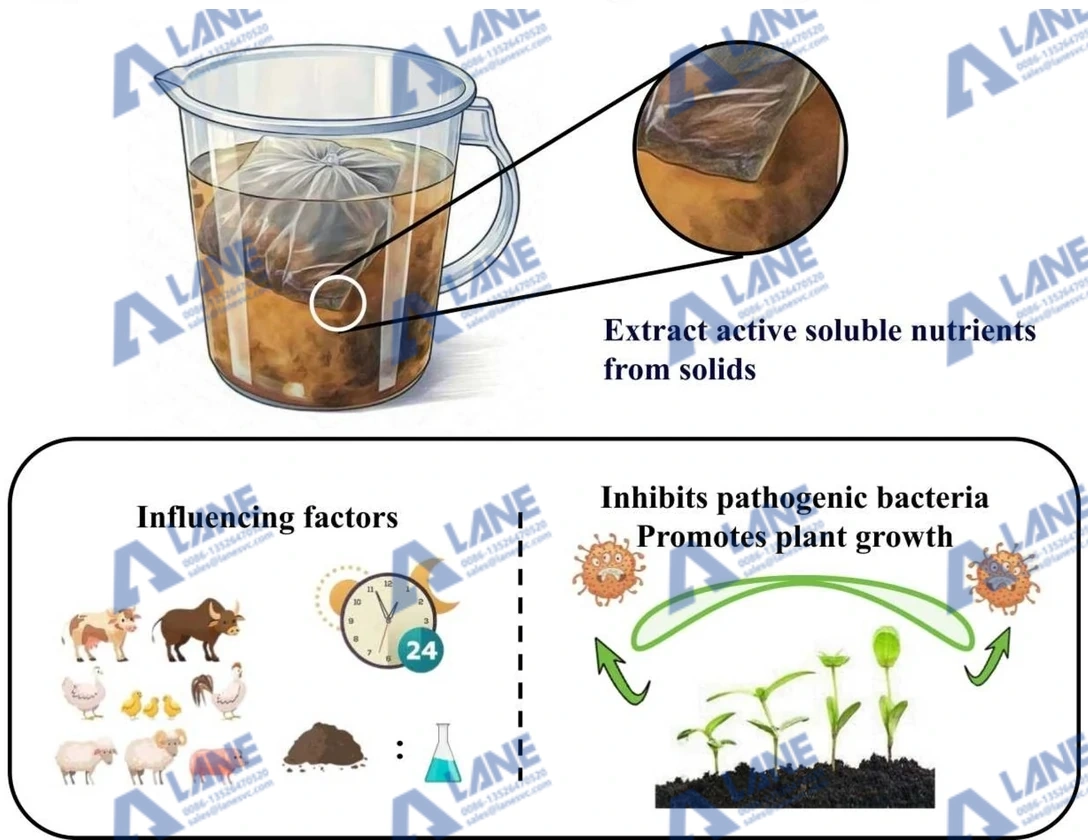

Compost tea is essentially a water extract of well-made compost. Unlike simple compost leachate, properly brewed compost tea is aerated and enriched to foster beneficial microbial populations such as bacteria, fungi, protozoa, and nematodes. These microorganisms play a vital role in nutrient cycling, root stimulation, and disease suppression.

The benefits include:

Enhanced nutrient uptake – Bioavailable forms of nitrogen, phosphorus, potassium, and micronutrients.

Improved soil structure – Increased microbial activity boosts soil aggregation and water retention.

Disease resistance – Beneficial microbes compete with and suppress soil-borne pathogens.

Globally, the demand for compost tea liquid fertilizer is growing rapidly, especially in the fields of organic agriculture, greenhouse horticulture and sustainable landscaping. This presents a huge opportunity for producers who can offer stable and high-quality products using efficient compost tea liquid fertilizer production lines.

The flexibility of a compost tea liquid fertilizer production line lies in its ability to adapt to available raw materials. Common inputs include:

| Category | Examples | Role in Compost Tea |

| Base Compost | Poultry manure compost, cattle manure compost, plant-based compost | Source of nutrients & beneficial microbes |

| Microbial Activators | Molasses, kelp extract, humic acid | Feeds and stimulates microbial growth |

| Nutrient Enhancers | Fish hydrolysate, seaweed extract, mineral additives | Boosts NPK levels & trace elements |

| Water | Clean, non-chlorinated water | Extraction medium |

By adjusting ingredient ratios, producers can create targeted formulations—for example, high-potassium compost tea for fruiting crops or microbe-rich blends for soil regeneration.

The compost tea liquid fertilizer production line follows a meticulously designed process to ensure that each batch of product is rich in nutrients, has active microorganisms, and maintains stable quality. The detailed steps of this process are as follows:

Step 1: Compost Selection & Pre-Processing

The process begins with selecting fully matured compost made from poultry manure, cattle manure, plant-based materials, or a combination of organic inputs. Immature compost is avoided, as it may contain phytotoxic compounds harmful to plants.

Equipment used: Compost screening machine or vibrating screener to remove large debris, stones, and non-degradable materials.

Goal: Ensure a uniform particle size for consistent nutrient extraction.

Step 2: Loading into Brewing Tanks

The screened compost is measured according to the batch size and loaded into stainless steel brewing tanks. These tanks are food-grade to prevent corrosion and maintain microbial safety.

Equipment used:Vertical Fermentation Tank (capacity: 500–20,000 liters).

Goal: Prepare for controlled brewing under optimal conditions.

Step 3: Water Filling & Aeration Setup

Non-chlorinated, clean water is added to the brewing tanks to create the extraction medium. The tanks are equipped with fine-bubble aeration systems that maintain dissolved oxygen above 6 ppm—essential for aerobic microbial growth.

Equipment used: Fine-Bubble Aeration System with air diffusers.

Goal: Create oxygen-rich conditions to encourage beneficial microbial activity.

Step 4: Adding Microbial Activators & Nutrient Boosters

During brewing, microbial activators such as molasses, kelp extract, or humic acid are introduced to feed and stimulate the beneficial microbes. This is done automatically for precision.

Equipment used: Automatic Nutrient Dosing System.

Goal: Accelerate microbial reproduction and nutrient solubilization.

Step 5: Continuous Agitation for Nutrient Release

To maximize nutrient extraction, the compost-water mixture must be kept in constant motion. Agitation prevents solids from settling and ensures even contact between compost and water.

Equipment used: Stainless Steel Mixing Tank or High-Shear Agitator integrated with the brewing tank.

Goal: Improve nutrient extraction efficiency and maintain suspension.

Step 6: Brewing Period Monitoring

The brewing phase typically lasts 24–48 hours depending on the formulation. During this time, temperature, oxygen levels, and pH are monitored closely to maintain optimal microbial growth.

Equipment used: Digital Control Panel with online monitoring sensors.

Goal: Ensure consistent, high-quality microbial population growth.

Step 7: Filtration & Clarification

Once brewing is complete, the liquid compost tea passes through a dual-stage filtration system. This removes larger particles, resulting in a smooth liquid that will not clog irrigation nozzles or sprayers.

Equipment used: Dual Filtration System (primary coarse filter + secondary fine mesh filter).

Goal: Achieve a clean, application-ready compost tea liquid fertilizer.

Step 8: Quality Testing

Samples from each batch are tested for microbial counts, nutrient composition, pH, and electrical conductivity (EC). This ensures the product meets market and regulatory standards.

Equipment used: Laboratory testing kits or in-house quality control lab.

Goal: Guarantee product quality, safety, and consistency.

Step 9: Storage & Packaging

The filtered compost tea is transferred to stainless steel holding tanks until it is ready for packaging. Packaging can be done in bottles, drums, or IBC totes, depending on the customer’s market requirements.

Equipment used: Automatic Liquid Filling Machine & Capping System.

Goal: Provide a market-ready product with extended shelf life.

Step 10: Distribution & Application

The final compost tea liquid fertilizer can be sold directly to farms, garden centers, or distributed through agricultural suppliers. It can be applied via drip irrigation, foliar spray, or soil drench.

Goal: Deliver nutrient-rich, microbially active fertilizer to improve soil health and crop productivity.

A well-designed compost tea liquid fertilizer production line depends on a few core pieces of equipment working together to deliver consistent quality and efficiency. LANE focuses on these essentials to keep your production smooth, cost-effective, and reliable.

1.Stainless Steel Brewing Tanks with Aeration System

The brewing tanks are the heart of the production line. Built from food-grade stainless steel, they maintain hygienic conditions and resist corrosion. Integrated fine-bubble aeration systems keep oxygen levels high, ensuring strong aerobic microbial growth throughout the brewing cycle.

2.Automatic Nutrient Dosing & Mixing System

This system accurately delivers microbial activators and nutrient boosters, while paddle mixers or agitators keep the mixture in motion for even nutrient extraction. This combination guarantees consistent quality in every batch.

After brewing, the compost tea passes through a dual-stage filtration system to remove particles. This ensures a smooth, clog-free product suitable for drip irrigation and foliar spraying.

4.Automatic Liquid Filling & Packaging Machine

The filtered compost tea is filled into bottles, drums, or IBC totes using an automatic filling system for precise, efficient packaging that preserves product freshness.

By focusing on these basic components, the compost tea liquid fertilizer production line can achieve high efficiency, excellent microbial quality and reliable long-term operation, without the need for unnecessary complexity.

North American Organic Farm Cooperative

A cooperative of organic farms in the Midwest relied on small-scale manual brewing for their compost tea. Demand from local farmers exceeded supply, prompting them to partner with LANE for a 5,000-liter compost tea liquid fertilizer production line. The system included aerated stainless steel tanks, automated nutrient dosing, and dual-stage filtration. Within a year, production increased by 65%, enabling the cooperative to expand distribution to regional organic retailers. Farmers reported improved crop health and reduced disease incidence.

Southeast Asian Export-Oriented Fertilizer Producer

A fertilizer company in Southeast Asia wanted to diversify its product line with organic-certified compost tea for export to Japan and Australia. LANE designed a 10,000-liter production line with advanced filtration and packaging suitable for international shipping. The company secured new export contracts, boosting annual revenue by 30%.

The global demand for sustainable crop nutrition solutions is growing rapidly, and the compost tea liquid fertilizer production line will play a key role in this transformation. According to industry reports, it is expected that the global market size of organic fertilizers will exceed 15 billion US dollars by 2030, among which the growth rate of liquid fertilizers (especially compost tea) will be among the highest. This growth is mainly driven by three factors:

Transition to regenerative agriculture – Farmers around the world are moving away from excessive reliance on synthetic fertilizers and turning to bioactive fertilizers that can restore soil health and biodiversity. Compost tea is not only nutritious but also rich in active microorganisms, and can significantly enhance soil fertility over the long term.

Government support and regulatory trends – Many countries are introducing subsidies, organic certification incentives, and stricter regulations on fertilizer usage. This creates a strong business case for investing in scalable compost tea liquid fertilizer production line technology.

Export opportunities – The markets in Europe, North America and parts of Asia are actively seeking organic-certified liquid fertilizers, which opens up the door for producers who can meet international quality standards.

For fertilizer manufacturers, cooperatives and investors in agricultural conglomerates, installing a compost tea liquid fertilizer production line not only ensures consistent high-quality output, but also creates opportunities for product diversification and entry into the high-end market.

Looking ahead, automation and precision brewing technologies will make compost tea production even more cost-efficient. LANE is already integrating real-time microbial monitoring systems, automated dosing, and energy-efficient aeration into its production lines to help clients stay ahead of market trends. In short, the market potential for compost tea liquid fertilizer is not just strong—it’s accelerating. Those who invest early in high-quality production technology will be best positioned to capture market share, build brand reputation, and meet the rising demand for sustainable, biologically active fertilizers worldwide.

As global demand accelerates, the difference between market leaders and followers will come down to production capability, product consistency, and technological adaptability. LANE’s compost tea liquid fertilizer production line solutions are engineered to help you meet these challenges head-on.

We provide turnkey systems—from plant layout design and equipment manufacturing to installation, training, and after-sales technical support. Our production lines are fully customizable, ranging from 500 liters to 20,000 liters per batch, and can be tailored for local or export markets. With stainless steel brewing tanks, fine-bubble aeration systems, dual filtration units, and automated nutrient dosing, LANE ensures that every batch meets both microbial quality and nutrient profile standards.

By partnering with LANE, you not only gain access to reliable, scalable technology but also benefit from our global experience—with successful projects delivered in over 20 countries. This ensures that your investment is future-proof, market-ready, and capable of delivering consistent profits year after year.

A compost tea liquid fertilizer production line is more than an industrial setup—it’s a gateway to producing high-value, sustainable fertilizers that improve soil health, boost yields, and reduce reliance on chemicals. LANE’s expertise ensures that every system is engineered for efficiency, microbial vitality, and long-term reliability. Whether you are a cooperative, a commercial farm, or a fertilizer manufacturer, partnering with LANE can transform compost tea production into a profitable, scalable business.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.