Synergies Between Biogas Plants and Carbon-Neutral liquid Fertilizer production Facilities

Table of Contents

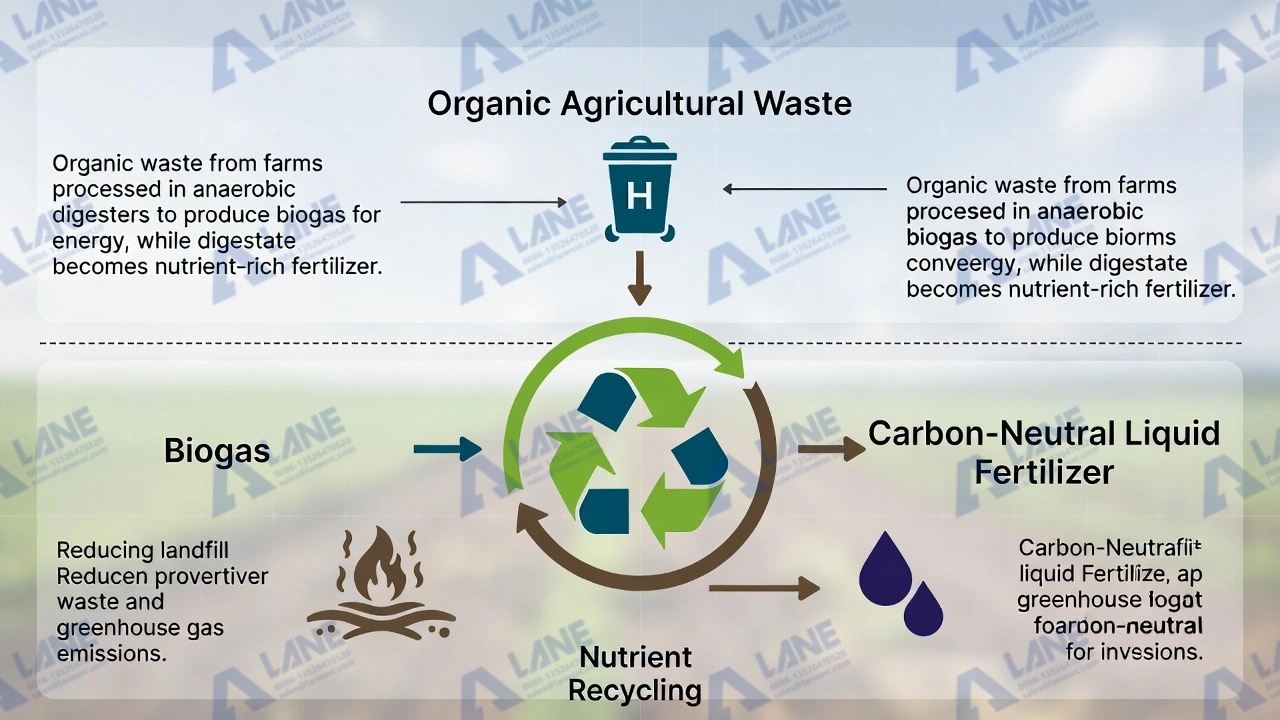

In the pursuit of carbon neutrality, industries are seeking integrated, circular solutions that minimize waste and maximize resource efficiency. This is driving innovation toward closed-loop systems where waste becomes a resource. One of the most popular closed-loop movements in the agriculture industry is the powerful synergy between biogas plants and facilities dedicated to carbon-neutral liquid fertilizer production. This model transforms organic waste streams into renewable energy and sustainable, nutrient-rich fertilizer. But this closed-loop system needs efficient and durable machines. LANE Heavy Industry’s production lines enable seamless, efficient carbon-neutral liquid fertilizer production while complementing biogas generation.

This article explores how this synergy works and how machinery from LANE Heavy Industry drives sustainability, scalability, and profitability in carbon-neutral liquid fertilizer production.

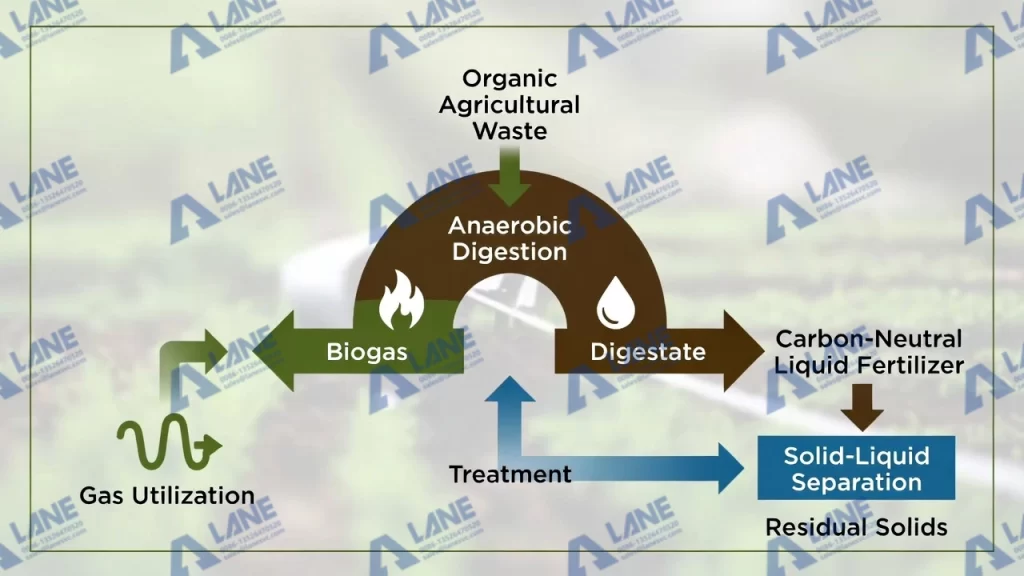

The synergy between a biogas digester and a carbon-neutral liquid fertilizer production facility is rooted in shared inputs and complementary outputs. A biogas plant anaerobically digests organic materials such as agricultural residues, animal manure, or food processing waste to produce biogas to be used for heat and power. It also creates a nutrient-dense liquid effluent called digestate.

Shared Feedstock: Both processes share the same organic waste streams. This simplifies the supply logistics.

Energy for Production: The biogas generated by the digester can be converted into electricity and heat. This can be used to power the adjacent liquid fertilizer production line, significantly reducing its operational energy costs and carbon emissions. You can use high-efficiency turbines that convert biogas into reliable on-site power and useful heat to power your carbon-neutral liquid fertilizer production.

Optimized Input: The digestate from the biogas process is a stabilized organic slurry which is rich in nutrients like nitrogen, phosphorus, and potassium. It serves as a superior raw material for advanced carbon-neutral liquid fertilizer production.

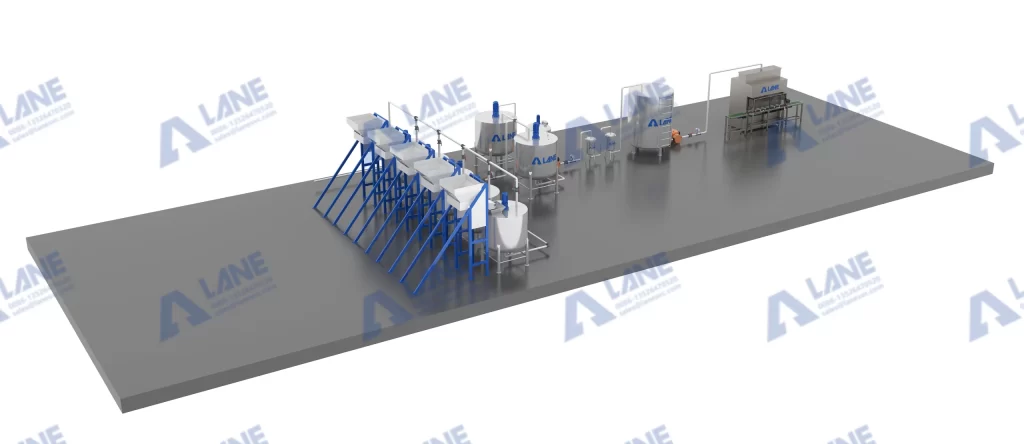

This is where specialized, scalable equipment bridges the gap between raw digestate and a market-ready, high-value product. LANE Heavy Industry, with its over 20 years of experience in fertilizer machinery production lines, provides the essential machinery.

The process within the fertilizer facility typically involves:

Pre-treatment & Fermentation: We provide further treatment facilities for the digestate. LANE’s production line includes crushers and specialized fermentation tanks equipped with temperature control and stirring devices to homogenize and stabilize the input material.

Enzymatic & Blending Stages: This is the most crucial stage of carbon-neutral liquid fertilizer production. Enzymatic tanks are used to further break down complex molecules, making nutrients more bioavailable. Precision blending tanks then allow for the addition of supplementary nutrients like N, P, K or amendments to create custom fertilizer formulas tailored to the crop of the manufacturer’s choice.

Filtration & Finishing: LANE uses dual multi-layer filtration systems to remove solids from the liquid fertilizer. This results in a pure, consistent liquid product suitable for precise application via irrigation systems. The production line concludes with automatic filling and packing systems.

This integrated approach powered by renewable biogas energy is the operational philosophy of true carbon-neutral liquid fertilizer production.

The combined model of biogas plants and carbon-neutral liquid fertilizer production offers compelling advantages:

Carbon-Neutrality: The fertilizer production’s energy demand is met by renewable biogas, not fossil fuels. This process also avoids greenhouse gas emissions that would result from the decomposition or disposal of the organic waste. This can be aligned with large-scale industrial goals to capture carbon to create nitrogen products.

Double Revenue Streams: You can generate income from selling electricity to the grid and from selling high-value, organic liquid fertilizer.

Waste Elimination and Circularity: It provides a complete, on-site solution for organic waste. It turns a disposal liability into profit centers and closes the nutrient loop on the farm or in the community.

This dual-value closed-loop system is already popular around the world. LANE Heavy Industry has delivered customized solutions for converting waste streams into fertilizer. This is a proven production line. Our customer in Vietnam wanted to turn his abundant soybean dregs into liquid fertilizer for local rice and vegetable cultivation. We provided him with this solution. We also provided technology and equipment to an African project aiming to solve both animal waste management and costly fertilizer imports.

We use tailored machinery to transform local organic waste into a consistent, carbon-neutral liquid fertilizer. This production line is viable and scalable, especially when paired with a local biogas energy source.

Q1: What types of waste are best for this integrated system?

A: The system is highly flexible. Ideal feedstocks include animal manure from livestock operations, crop residues, food processing by-products (like soybean dregs), and dedicated energy crops. The key is consistent local availability.

Q2: Can the fertilizer production line be customized for different raw materials?

A: Absolutely. LANE Heavy Industry specialize in customizing production lines based on the specific characteristics of the client’s raw material, desired output capacity, and final product specification.

Q3: How does using biogas make the fertilizer “carbon-neutral”?

A: Carbon-neutral liquid fertilizer production is achieved by using renewable biogas energy to power the grinding, pumping, mixing, and filtration processes. This displaces fossil-fuel-based grid electricity or on-site diesel generators, effectively neutralizing the carbon emissions from the manufacturing phase.

Q4: What is the role of companies like GUASCOR or Aurelia in this system?

A: These companies provide the critical technology to convert biogas into usable energy. GUASCOR’s robust biogas engines or Aurelia’s high-efficiency microturbines generate the electricity and heat that power the LANE fertilizer production equipment, enabling the integrated, energy-self-sufficient facility.

Q5: Is this model feasible for a single large farm or only for industrial operators?

A: The model is scalable. A large dairy or swine operation could implement a system to handle its own waste. Alternatively, a centralized facility can serve multiple farms and waste producers within a region, improving economic viability.

Q6: What is the final product of this integrated system?

A: The primary product is a high-quality, organic liquid fertilizer that is easy for plants to absorb and can be applied through modern irrigation systems. The consistent quality achieved through controlled fermentation and precise blending, as seen in LANE’s projects, makes it a reliable tool for sustainable agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.