Building a Liquid Fertilizer Line with EU Standards: Precision, Safety, and Sustainability

Building a liquid fertilizer line with EU standards is one of the best ways for modern fertilizer manufacturers to enter the European market and improve their production quality. The European Union has strict regulations for fertilizer products — not only on nutrient content and safety but also on how the fertilizer is produced.

A well-designed liquid fertilizer line with EU standards ensures that every stage — from raw material handling to packaging — meets safety, environmental, and efficiency requirements. With growing attention to sustainability, more companies are upgrading their systems with CE-certified equipment, smart control systems, and eco-friendly processes.

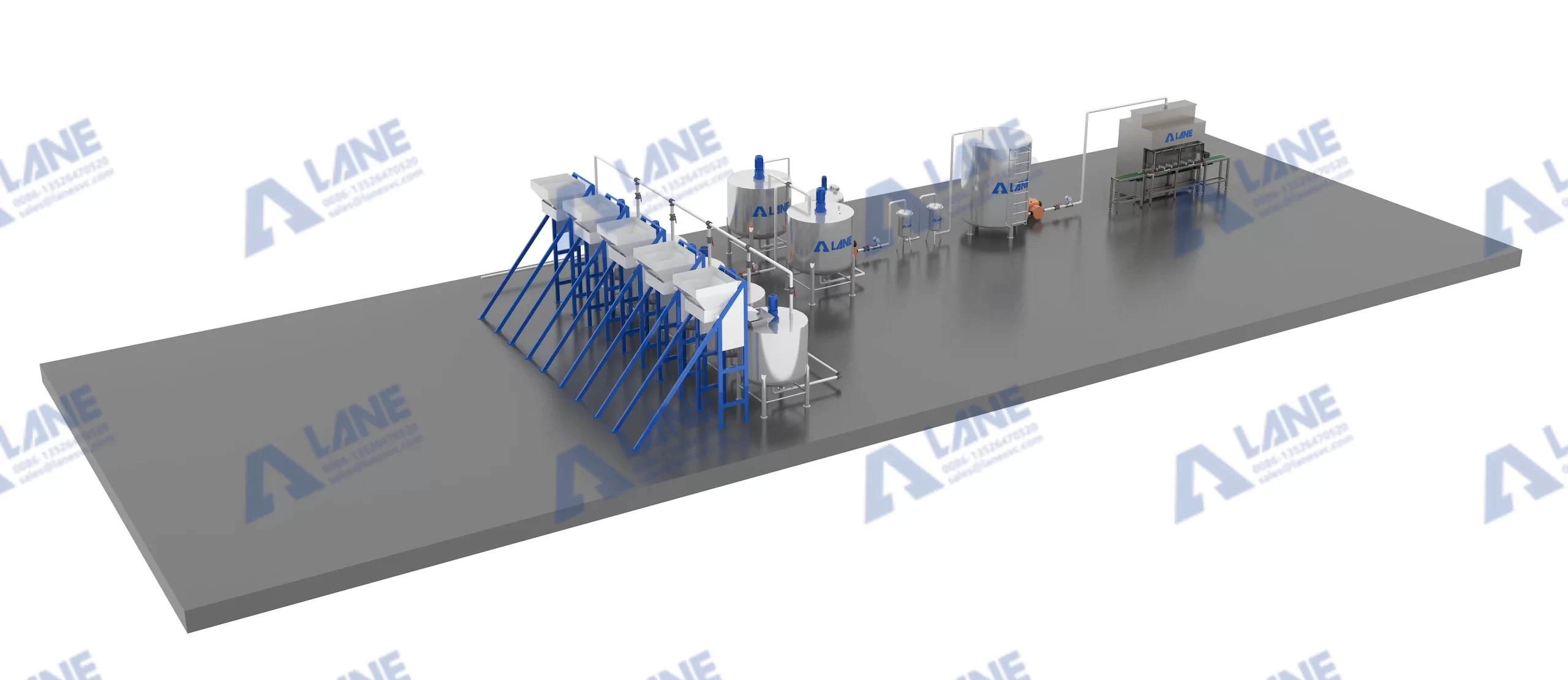

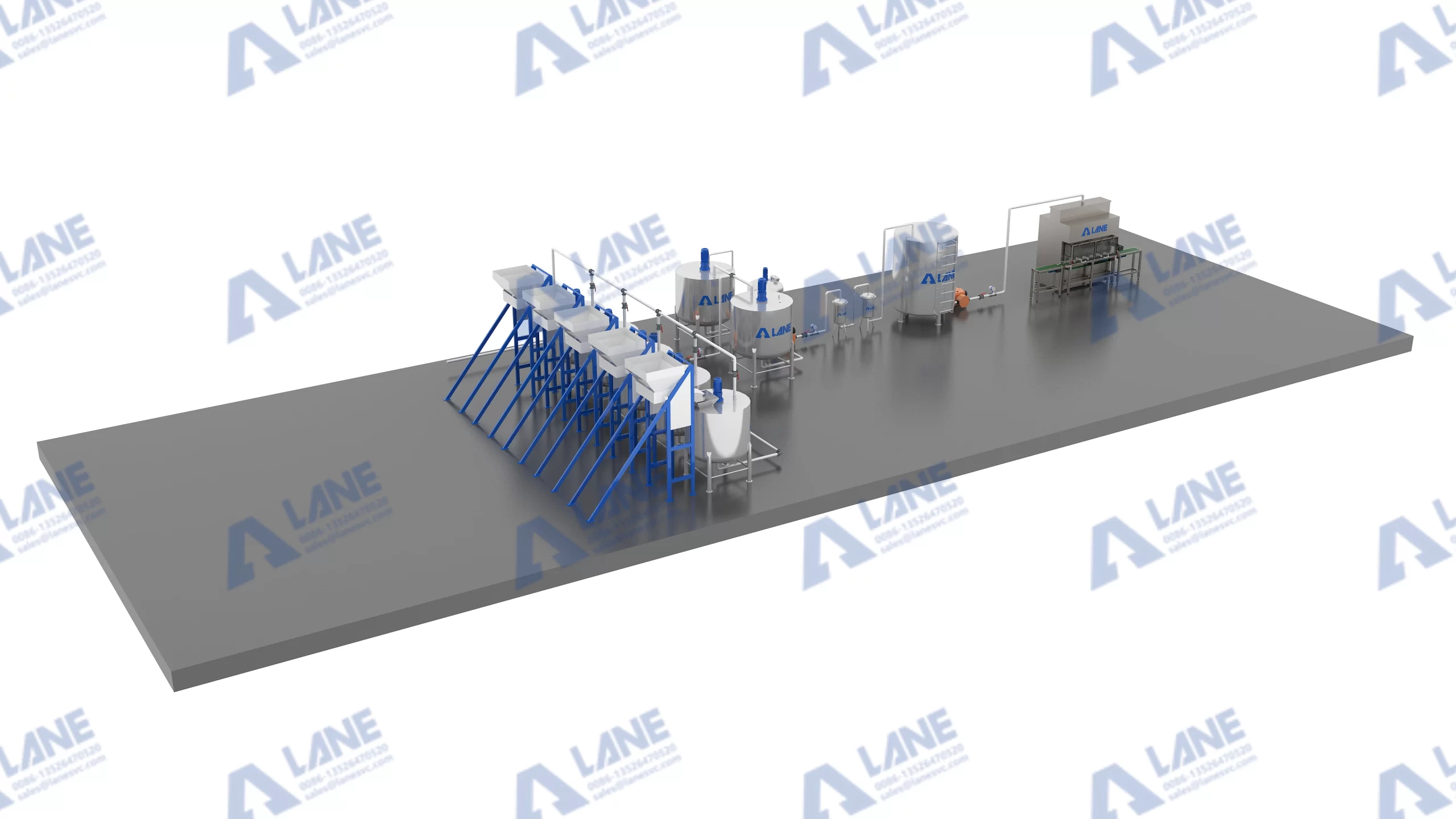

A liquid fertilizer line with EU standards is a complete production system used to make water-soluble or suspension fertilizers that comply with the European Fertilizing Products Regulation (EU 2019/1009) and related directives.

It involves several connected machines that prepare, mix, filter, and package liquid fertilizers — all under precise control to ensure consistent quality and safety.

EU standards focus on:

Product purity (no harmful residues or heavy metals)

Accurate nutrient labeling and consistency

Worker and environmental safety

Traceable and CE-marked equipment

By using EU-certified systems, manufacturers can easily export their products to European markets, increasing their competitiveness and credibility.

To build a liquid fertilizer line with EU standards, you need several core machines that work together in sequence. Each piece of equipment has a specific role in ensuring quality, consistency, and compliance.

1.Raw Material Storage and Feeding System

Raw materials like urea, potassium chloride, phosphoric acid, and trace elements are stored in stainless steel tanks (usually 304 or 316 grade).

Dosing pumps and flow meters ensure accurate feeding amounts.

Automated systems prevent human error and maintain correct NPK ratios.

LANE Heavy Industry’s feeding systems use CE-certified pumps and corrosion-resistant piping to meet EU safety requirements.

2.Liquid Fertilizer Mixing Tank

The mixing tank is the heart of the production line. Here, raw materials are mixed and dissolved to form the fertilizer solution.

Built from 304/316 stainless steel to resist corrosion.

Equipped with high-speed agitators or paddle mixers for even blending.

Automatic pH and temperature sensors ensure proper chemical balance.

LANE’s liquid fertilizer mixer combines energy-efficient motors and precise control systems to produce uniform fertilizer batches.

3.Heating and Reaction System

Some fertilizers (like ammonium phosphate or urea-based formulas) need heat or chemical reaction.

The heating reactor tank is used to maintain temperature between 60–90°C.

Equipped with steam coils or electric heating elements, along with pressure safety valves and insulation.

CE-certified controls monitor the reaction safely.

This process ensures all nutrients are fully dissolved and chemically stable.

4.Inline Homogenizer or Stirring Pump

After mixing, the fertilizer passes through an inline liquid fertilizer homogenizer.

It breaks down any remaining particles or bubbles.

Ensures a smooth and stable product that doesn’t separate during storage.

Optional rotor-stator design for high-shear mixing.

This is essential for suspension fertilizers and thick nutrient blends.

5.Filtration System

Before packaging, the solution goes through a dual filter to remove impurities.

Mesh filters or cartridge filters catch undissolved solids.

Prevents clogging of sprayers and ensures a clear, sediment-free fertilizer.

LANE provides both single-stage and automatic backwash filter options.

6.Storage Tank System

The finished fertilizer is transferred into storage tanks equipped with slow agitators.

Keeps the solution homogeneous before packaging.

Stainless steel tanks prevent corrosion and contamination.

Optional cooling system to maintain product stability.

LANE’s storage systems are modular — easy to expand if production capacity grows.

7.Automatic Filling and Packaging Machine

Finally, the fertilizer is filled into bottles, drums, or IBC tanks using an automatic filling machine.

CE-marked PLC control system for accurate volume measurement.

Drip-free nozzles and fast capping system.

Optional labeling machine for QR codes, batch numbers, and CE marks.

This guarantees traceability — an important requirement under EU fertilizer regulations.

Here’s a typical process flow for a liquid fertilizer line with EU standards:

Raw Material Preparation

Urea, phosphates, and other chemicals are dissolved in water in separate mixing tanks.

Feeding and Mixing

The system automatically doses ingredients into the main mixing tank according to formula settings.

Heating and Reaction

For formulations that need chemical bonding, the reactor tank heats and stirs the solution evenly.

Homogenizing and Filtering

The fertilizer passes through the inline homogenizer and filter system to ensure smooth texture.

Cooling and Storage

The mixture is cooled in storage tanks with agitators to maintain stability.

Filling and Packaging

The automatic filling machine bottles the fertilizer for sale, adding labels and traceable barcodes.

All systems are monitored by a PLC control cabinet, ensuring stable operation, real-time data recording, and easy maintenance.

LANE Heavy Industry is an experienced manufacturer specializing in organic and liquid fertilizer production lines. The company designs and supplies liquid fertilizer lines with EU standards that are fully automated, energy-efficient, and built for long service life.

Why Choose LANE’s Liquid Fertilizer Line with EU Standards?

CE & ISO Certified Equipment – all machinery meets EU regulations.

High-Quality Materials – stainless steel 304/316 tanks and pipelines.

Precise Process Control – PLC-controlled dosing, mixing, and filtration.

Flexible Customization – supports NPK, amino acid, humic acid, or biofertilizer formulations.

Turnkey Solutions – design, manufacturing, installation, and training included.

LANE also provides detailed documentation and technical support for CE certification audits — a key advantage for exporters targeting the European market.

Building a liquid fertilizer line with EU standards is an essential step for any fertilizer manufacturer aiming for quality, safety, and global competitiveness. These systems guarantee consistent nutrient content, low environmental impact, and full compliance with European regulations.

With advanced engineering, durable materials, and strong technical experience, LANE Heavy Industry provides turnkey fertilizer solutions that help businesses achieve CE certification and expand into new markets with confidence.

Whether you are upgrading an existing factory or planning a new project, LANE’s EU-standard liquid fertilizer production lines combine performance, precision, and sustainability for the future of agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.