Building a Sustainable Future: The Role of the Modern Liquid Biofertilizer Manufacturing Plant

Agriculture contributes 22% of global anthropogenic greenhouse gas emissions, with chemical fertilizers accounting for 10.6% of these agricultural emissions. The over-reliance on chemical fertilizer has led to degraded soils, polluted waterways, and significant gas emissions. Because of this, governments all over the world are giving subsidies to biofertilizer manufacturing plants. It’s a facility dedicated to producing living, microbial solutions that nourish the soil and plants naturally.

Liquid biofertilizers, with their stable microbial activity and high nutrient utilization rate, outperform traditional chemical fertilizers and solid organic fertilizers in environmental friendliness. The modern agriculture system is moving toward advanced liquid biofertilizer manufacturing plants, which offer superior consistency, ease of application, and microbial viability.

Liquid biofertilizers consist of beneficial microorganisms like nitrogen-fixers, phosphate-solubilizers, and potash-mobilizers in suspended liquid form. Their advantages are:

Producing advanced biological fertilizer requires precision, sterility, and scalability. This is where the engineering of a biofertilizer manufacturing plant becomes critical.

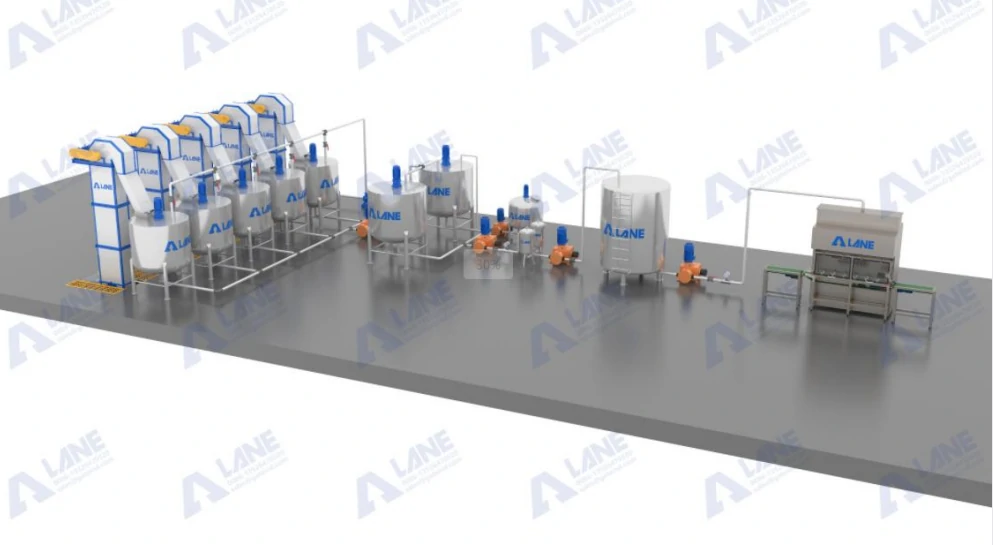

A modern liquid biofertilizer plant is more than a factory; it’s a controlled biological ecosystem. The process must maintain pure microbial cultures, optimize their growth, and formulate them into a product that remains effective until it reaches the farmer’s field. The core stages include: media preparation, fermentation, biomass harvesting, blending & formulation, and sterile packaging. Each stage demands specialized, reliable machinery to prevent contamination and ensure product potency.

To achieve high throughput and consistent quality, a biofertilizer manufacturing plant must have precision engineered machinery. LANE Heavy Industry offers integrated production lines that are precise, efficient and corrosive resistant. Here’s how our machinery orchestrates the process:

LANE incorporates many quality control measures for their biofertilizer manufacturing plants. In-line sensors monitor parameters, and samples are routinely taken to the plant’s laboratory. LANE trains your technicians and they verify microbial purity, count CFUs, and test for contaminants. This end-to-end control, enabled by reliable and consistent machinery, is what separates a professional-grade biofertilizer manufacturing plant from a makeshift operation.

The modern liquid biofertilizer manufacturing plant is more than a production facility. It represents sustainable agriculture. It reduces dependency on energy-intensive synthetic fertilizers, revitalizes soil microbiomes, and helps sequester carbon. By leveraging LANE Heavy Industry’s advanced production line, you can transform organic waste into high-efficiency fertilizers, cut emissions, improve soil health, and boost agricultural productivity.

Q1: What is the minimum land and investment required to set up a liquid biofertilizer manufacturing plant?

A: The requirements vary by scale. A small-to-medium plant with a modular line, such as those offered by LANE Heavy Industry, might require 5,000-10,000 sq. ft. of space and a significant investment in machinery, sterile infrastructure, and laboratory setup. A detailed project report from a machinery supplier is essential for accurate planning.

Q2: How critical is the choice of machinery for the success of the plant?

A: It is paramount. Machinery that cannot maintain sterility, control fermentation parameters precisely, or ensure homogeneous mixing will lead to product failure, contamination, and financial loss. Investing in engineered solutions from experienced providers like LANE Heavy Industry mitigates these risks and ensures process reliability.

Q3: Can a biofertilizer plant be profitable?

A: Yes, with growing global demand for organic and sustainable agricultural inputs, the market is expanding rapidly. Profitability depends on factors like plant scale, production efficiency, product quality, and effective marketing to the right agricultural segments. Efficient, high-quality production is the first foundation of profitability.

Q4: What is the shelf life of liquid biofertilizers produced in such a plant?

A: In a well-designed biofertilizer manufacturing plant with proper formulation and aseptic packaging, liquid biofertilizers can have a shelf life of 12-24 months when stored away from direct sunlight and extreme temperatures. The quality of the formulation stage directly impacts this.

Q5: Does LANE Heavy Industry provide support beyond machinery supply?

A: Reputable industrial machinery providers like LANE typically offer comprehensive support packages, including installation supervision, operational training, maintenance protocols, and technical assistance. It’s crucial to discuss these service-level agreements during the planning phase.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.