Boosting Aquaculture Vitality with aquaculture humic potassium fertilizer

Using aquaculture humic potassium fertilizer in fish and shrimp production has become an increasingly popular approach to improving water stability and biological performance. Because aquaculture systems rely heavily on balanced water chemistry and microbial activity, aquaculture humic potassium fertilizer provides a natural, gentle, and highly effective method to enhance pond health. Within the first steps of preparing such a liquid product, farmers must understand the raw materials, the production workflow, and the equipment required to transform humic sources—especially potassium fulvate—into a stable liquid fertilizer that functions well in live aquatic environments. As the demand for environmentally friendly solutions grows, the role of aquaculture humic potassium fertilizer becomes even more prominent.

At the core of this technology is potassium fulvate, a highly soluble component extracted from leonardite or other humic-rich organic materials. When processed properly, aquaculture humic potassium fertilizer can be added directly to ponds, biofloc systems, recirculating aquaculture systems (RAS), and nursery tanks. It offers benefits such as improving water buffering capacity, reducing toxic ions, energizing beneficial microorganisms, and enhancing animal resistance. To achieve these results, producers must use equipment designed for stable mixing, reaction control, impurity removal, and safe storage. As the global aquaculture sector grows, the adoption of aquaculture humic potassium fertilizer is expected to increase steadily.

Lane, a seasoned manufacturer with more than two decades of experience in fertilizer machinery in China, supports producers looking to build or upgrade facilities for liquid humic potassium products. With professional engineering capabilities and a long-standing focus on turnkey fertilizer lines, Lane offers solutions from system design to installation and after-sales support. The company upholds ISO 9001 and CE standards and supplies reliable equipment for organic, compound, and NPK fertilizer processing. Their integrated service and customized approach make them valuable partners for factories preparing aquaculture humic potassium fertilizer.

Humic substances are naturally occurring organic compounds derived from the decomposition of plant materials. When processed into a soluble potassium form, they exhibit the following advantages:

Water quality stabilization

Aquaculture humic potassium fertilizer binds heavy metals, moderates pH, and enhances buffering capacity, making water fluctuations less stressful for fish and shrimp.

Improvement of microbial balance

Beneficial bacteria thrive when fulvic components are available. This leads to better organic matter breakdown and a reduction in ammonia and nitrite levels.

Reduction of stress in aquatic animals

Fulvic and humic molecules reduce oxidative stress, improving immune response and lowering mortality.

Enhanced feed efficiency

Better water quality increases appetite and digestion, indirectly raising production.

Improved larval survival

In nursery stages, even small concentrations of aquaculture humic potassium fertilizer support healthier microbial films and protect fragile larvae.

To manufacture aquaculture humic potassium fertilizer, the following raw materials are typically used:

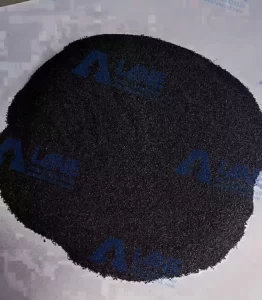

Potassium fulvate (main active ingredient)

Purified water or softened water

Potassium hydroxide (for pH adjustment and solubilization)

Optional chelating minerals (Mg, Ca, Fe at low levels suitable for aquatic use)

Preservatives (if required for long-term storage)

The goal is to maintain complete solubility and stability so the solution can disperse smoothly into water bodies without forming residue that may harm aeration systems or pond bottoms.

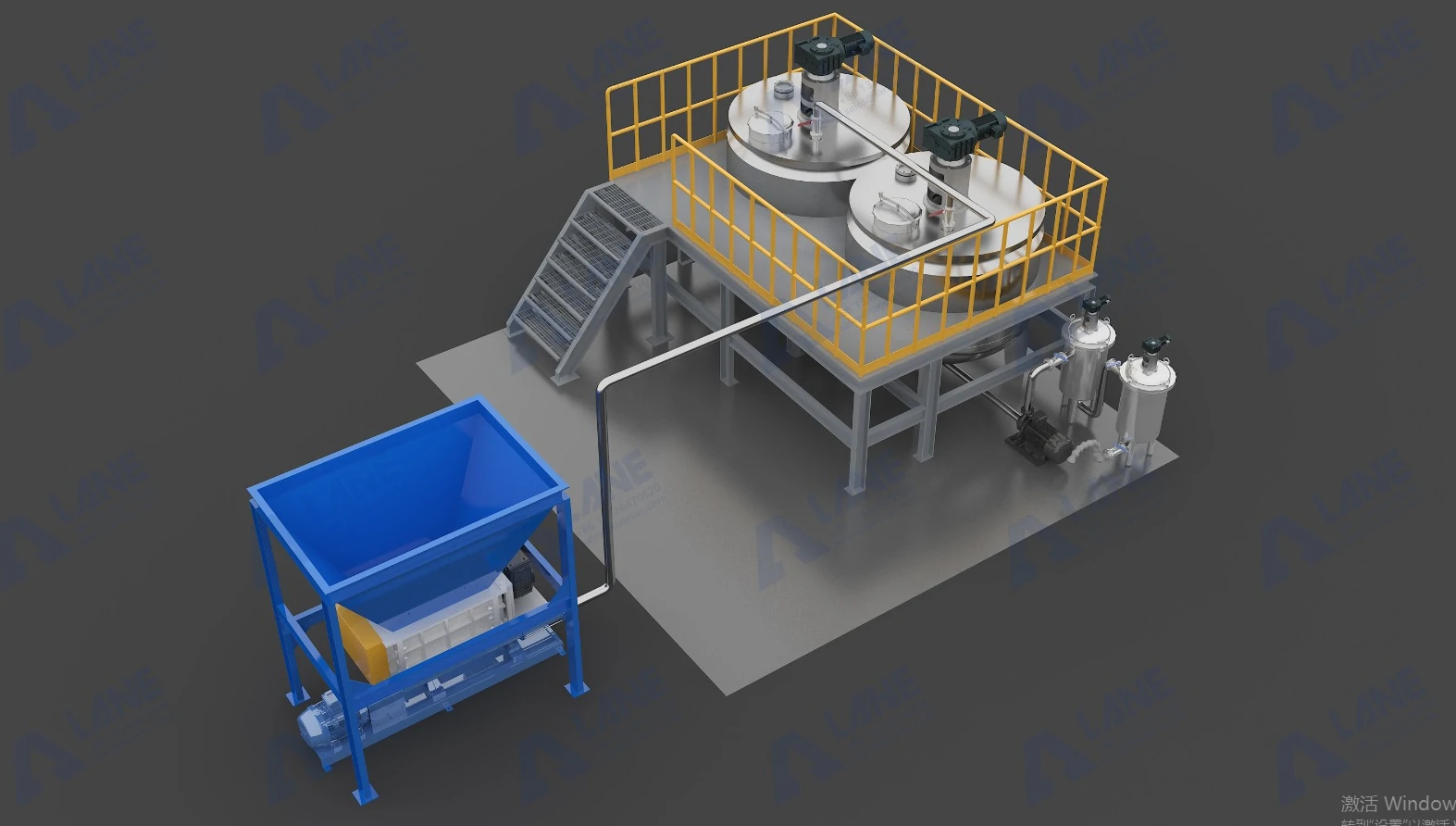

Below is the simplified, direct list of essential equipment for producing aquaculture humic potassium fertilizer. Each item plays a clear functional role:

Dissolving Tank with Heating / Agitation

Used to dissolve potassium fulvate thoroughly, adjust pH, and ensure full reaction.

Prevents clumps and accelerates homogenization, ensuring that the active ingredients remain uniformly suspended.

Filtration system (simple mesh or bag filter)

Removes oversized impurities that could clog dosing pumps or block aeration lines in ponds.

Storage tank with anti-corrosion lining

Keeps the finished aquaculture humic potassium fertilizer stable and sediment-free.

Automatically fills drums, IBCs, or bottles for easy transport to farms.

Optional inline quality-control meter

Measures pH, density, and solubility in real time to maintain product consistency.

Lane can supply the complete set of this equipment, adjusting specifications according to batch size—whether 1 ton per day or over 50 tons per day. Their engineering team helps producers plan workflow layouts so that aquaculture humic potassium fertilizer lines remain efficient and cost-effective.

To ensure the product performs safely in aquaculture environments, several important details must be controlled during production.

Maintain full solubility

Any undissolved humic matter may form sludge in ponds. Producers should use sufficient mixing power and filter the product before packaging.

Control pH carefully

The typical target is pH 7–9, which prevents irritation to aquatic animals and maintains stability of the aquaculture humic potassium fertilizer.

Avoid high mineral concentrations

Excessive calcium, magnesium, or iron may interfere with aeration or biofloc formation, so mineral additives must be carefully controlled.

Use softened or purified water

Hard water causes precipitation. Soft water keeps the solution smooth and transparent.

Ensure microbial safety

No unwanted bacteria or contaminants should remain in the raw materials or equipment.

Keep viscosity moderate

The liquid should remain easy to inject through pumps, automatic dosing systems, or simple manual application.

Once produced, aquaculture humic potassium fertilizer can be applied in several ways:

Pond conditioning

Added during pond preparation or water filling to improve baseline water quality.

Routine maintenance

Regular low-dose applications stabilize microbial communities.

Stress-relief dosing

Applied during temperature fluctuations, after storms, or following handling and grading of fish/shrimp.

Biofloc enhancement

Humic materials promote the growth of flocs that trap nutrients and convert waste into edible protein sources.

Seedling / nursery tank support

Helps create a gentle, protective environment for larvae and fry.

Because aquaculture humic potassium fertilizer interacts naturally with water and beneficial microbes, it is considered safer than many chemical additives and contributes to eco-friendly aquaculture practices.

Integrating aquaculture humic potassium fertilizer into a production system brings several specific advantages:

Lower ammonia and nitrite levels

By stimulating beneficial bacteria, harmful nitrogen compounds are converted more quickly.

More stable pH

Reduces daily fluctuations that cause fish stress.

Better stress resistance

Shrimp and fish exposed to humic substances show stronger resistance to environmental stressors.

Improved water color and clarity

Creates a natural “tea color” that shades harmful algae and stabilizes plankton.

Reduced disease outbreaks

Humic molecules support immune function and reduce pathogen activity.

Higher survival and growth rates

The overall effect is healthier ponds and more consistent yields.

With continued use, farmers report improved feed conversion ratios, more balanced biofloc performance, and significantly lower mortality—proof of how effective aquaculture humic potassium fertilizer can be.

Producers who aim to manufacture aquaculture humic potassium fertilizer at scale rely on dependable equipment and system planning. Lane provides:

Over 20 years of fertilizer equipment manufacturing experience

Custom engineering design for complete liquid and solid fertilizer lines

ISO 9001 and CE–standard machinery

Installation, training, maintenance, and long-term service

Expertise in organic, NPK, and compound fertilizer production equipment

By offering integrated solutions rather than single machines, Lane ensures that aquaculture humic potassium fertilizer plants operate smoothly and maintain consistent quality.

As global aquaculture continues its rapid expansion, producers seek more natural, environmentally responsible tools that improve water quality and animal performance. Aquaculture humic potassium fertilizer fits perfectly into this trend. When produced with proper raw materials, correct processing techniques, and reliable equipment, it transforms pond ecosystems into cleaner, more stable, and more productive environments.

With its ability to regulate water chemistry, support beneficial microbes, enhance animal immunity, and encourage healthy growth, aquaculture humic potassium fertilizer is becoming an essential part of modern fish and shrimp farming. Combined with Lane’s manufacturing expertise and comprehensive support, producers can confidently build efficient, durable fertilizer lines that serve the aquaculture industry for many years.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.