Investing in Amino Acid Liquid Fertilizer Production | LANE Heavy Industry Machinery

Sustainable agriculture is getting popular day by day because of the continuous favorable treatments from governments all over the world. Farmers and agribusinesses are also becoming aware of the usefulness of sustainable farming. Among the sustainable methods, the bio-stimulant industry is growing rapidly. Bio-stimulants enhance plant nutrition efficiency, abiotic stress tolerance, and increase overall crop quality. Among the bio-stimulants, Amino Acid Liquid Fertilizer has become popular among investors due to its high efficiency, environmental friendliness, and multi-functional advantages.

Unlike traditional fertilizers, Amino Acid Liquid Fertilizer can be directly absorbed by plants. It improves nutrient utilization while enhancing crop stress resistance and soil health. But to produce Amino Acid Liquid Fertilizer, industrial-grade precision machinery is required. This article explores the business case and practical pathway for investing in an Amino Acid Liquid Fertilizer production line with the help of LANE Heavy Industry.

Unlike traditional NPK fertilizers that feed the soil, amino acid-based products work directly on the plant’s physiology. It is made from hydrolyzed protein sources (like leather waste, feathers, or plant-based meals). It provides building blocks for proteins, enzymes, and chlorophyll. They act as:

The market demand for Amino Acid Liquid Fertilizer is driven by the need for higher productivity on limited land and the reduction in chemical inputs. An Amino Acid Liquid Fertilizer line positions your business at the intersection of profitability and sustainability.

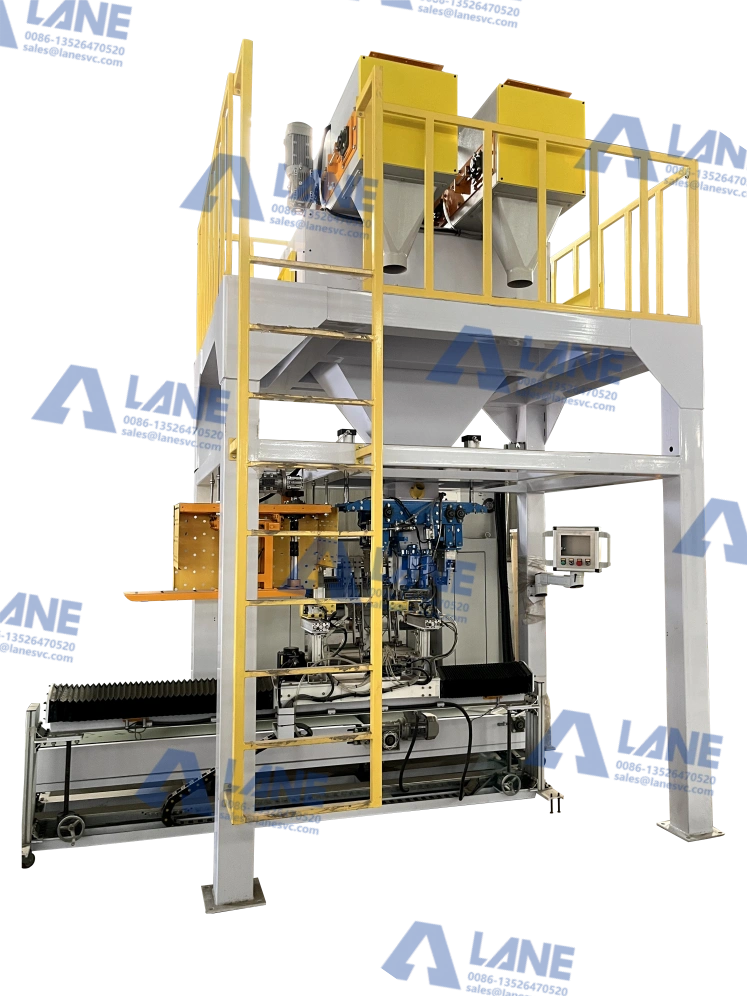

Amino Acid Liquid Fertilizer production is complex and needs proper care. Success depends on a reliable, efficient, and scalable production line. Their expertise in designing integrated processing systems ensures a seamless flow from raw material to finished product.

A complete Amino Acid Liquid Fertilizer production line from LANE typically integrates several stations:

The core production process of the LANE Amino Acid Liquid Fertilizer is:

Initial investment centers on machinery, facility, raw material sourcing, and certification. A turnkey solution from LANE Heavy Industry ensures reliability and lower long-term maintenance costs.

Key Revenue Drivers:

ROI is accelerated by production efficiency. Machines made by LANE Heavy Industry minimize labor, energy, and raw material waste. It improves your gross margin. You can expect payback periods ranging from 2 to 4 years based on scale and market penetration.

The Amino Acid Liquid Fertilizer business stands at the intersection of agricultural transformation and environmental protection, with huge market potential. Investing in an Amino Acid Liquid Fertilizer production line is an economically viable decision which gives you entry to a market defined by growth, innovation, and sustainability. With rational planning of raw material supply, product positioning, and channels, the project is expected to achieve sustainable profits while contributing to green agriculture development.

Q1: What is the primary advantage of using LANE Heavy Industry machinery for this production line?

A1: LANE Heavy Industry provides integrated, industrial-grade machinery designed for continuous, high-volume production. Their focus on durability, process control, and after-sales support minimizes downtime, ensures product consistency, and protects your long-term investment, which is crucial for competitive manufacturing.

Q2: What are the main raw material sources for Amino Acid Liquid Fertilizer?

A2: Common sources include protein-rich agricultural by-products like feather meal, leather hydrolysis waste, soybean meal, and fish waste. The choice depends on local availability, cost, and the desired amino acid profile in the final product.

Q3: How technical is the production process? What kind of expertise do I need?

A3: The core hydrolysis and formulation processes require technical knowledge in chemistry and process engineering. LANE Heavy Industry often provides comprehensive training and process guidance. Hiring a production chemist or agronomist is advisable for quality control and formulation development.

Q4: What is the typical minimum viable production scale for profitability?

A4: While small batch systems exist, a commercially viable operation often starts with a capacity of 1,000 to 5,000 liters per batch. This scale allows you to supply local distributors and larger farms while achieving economies of scale. LANE can design lines scalable from pilot to full industrial output.

Q5: How do I ensure the quality and efficacy of my Amino Acid Liquid Fertilizer?

A5: Quality is controlled at multiple stages: verifying raw material protein content, monitoring hydrolysis parameters (time, temperature, pH), testing the final product’s amino acid concentration via HPLC, and conducting plant trials. Investing in a basic in-house lab is essential for consistent quality.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

Latest Posts

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.