Agriculture Liquid Fertilizer Production Technology: Driving the Next Era of Sustainable Farming

Agriculture liquid fertilizer production technology is transforming the way farmers feed their crops and manage nutrient cycles. In modern agriculture, efficiency, precision, and sustainability are no longer optional but are crucial. Liquid fertilizers have become a key tool for improving nutrient absorption, optimizing application methods, and reducing environmental impact. By converting raw nutrients into highly soluble, plant-available solutions, this technology bridges the gap between yield performance and environmental responsibility.

From large-scale crop farms in the Midwestern United States to intensive horticultural operations in Asia, agricultural liquid fertilizer production technology is helping producers maximize nutrient efficiency while reducing waste. Through appropriate systems, organic or inorganic nutrients can be transformed into liquid forms that are easy to store, transport, and apply through modern irrigation and spraying systems.

Liquid fertilizers are not a new concept, but their production has made significant progress over the past decade. The driving force behind this evolution is:

The demand for precision agriculture – farmers now need nutrient delivery systems that can meet the needs of plants at different growth stages.

The rising cost of inputs – synthetic fertilizers are expensive, so efficient use of nutrients is crucial.

Sustainable development goals – Governments and markets are actively encouraging practices that reduce runoff, leaching, and emissions.

Integration with modern equipment – drip irrigation, foliar spraying systems, and water-fertilizer integration devices can all be seamlessly integrated with liquid fertilizer formulations.

By investing in the production technology of agricultural liquid fertilizers, growers can produce customized blended fertilizers that are suitable for their specific crops, soil and climatic conditions.

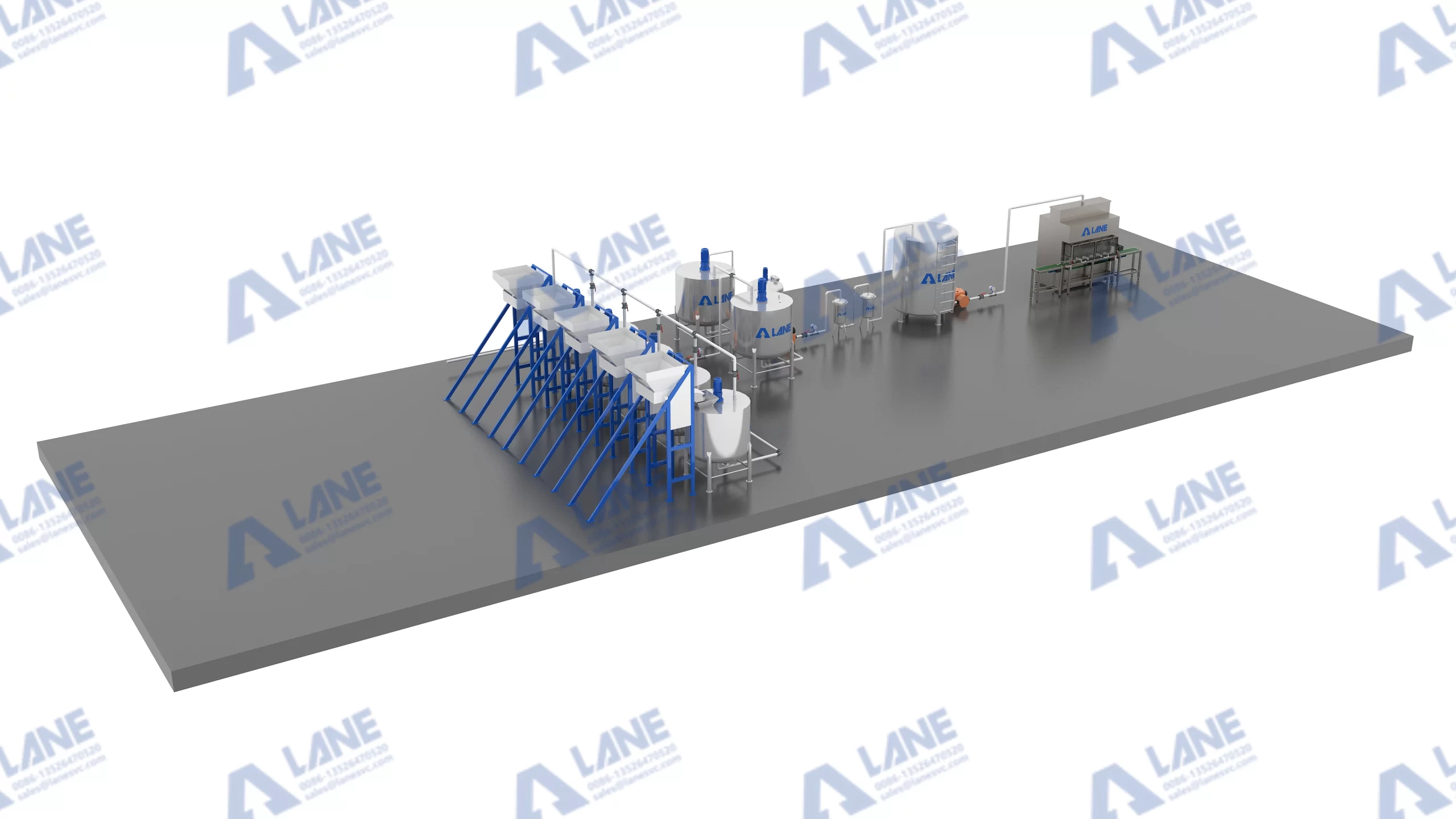

The process of creating high-quality liquid fertilizers from organic or inorganic raw materials involves several key stages, each critical for optimizing the nutrient availability, ensuring pathogen control, and maintaining efficiency. Below is a detailed breakdown of the core workflow, with the specific equipment used at each stage:

1.Raw Material Collection and Pre-Treatment

The process begins with the collection of raw materials such as agricultural residues, livestock manure, or food waste. In this stage, it’s crucial to remove any non-organic contaminants like plastic or metal debris. Pre-treatment steps also involve adjusting the moisture content of the waste for better processing.

Equipment used:

Solid-Liquid Separator: Separates liquids from solid organic materials, reducing moisture content and preparing the raw material for fermentation or composting.

Shredders or Hammer Crushers: Breaks down large organic matter into smaller particles to increase surface area, promoting faster nutrient release.

2.Pathogen Sterilization

To ensure the liquid fertilizer is safe for agricultural use, particularly in organic farming, pathogen control is essential. Heat or UV light is used to eliminate harmful microorganisms and pathogens.

Equipment used:

UV Sterilizer: UV light kills bacteria, viruses, and other pathogens in the liquid material, ensuring the safety of the final product.

Thermal Pasteurizer: A heat-based method where the slurry is heated to kill pathogens without damaging essential nutrients.

3.Nutrient Extraction and Fermentation

At this stage, organic matter undergoes fermentation. Microorganisms break down complex organic compounds into simpler, plant-available nutrients. This stage also helps stabilize the raw material and neutralize odors.

Equipment used:

Anaerobic Digester: A sealed system where microorganisms break down organic matter without oxygen, converting it into nutrient-rich liquid fertilizer.

Aerobic Fermentation Tank: For aerobic composting, where oxygen is required to break down the organic waste into a stable, nutrient-rich form.

4.Filtration and Refinement

After fermentation, the slurry may still contain solid particles or large debris. Filtration is necessary to ensure the final liquid fertilizer is free from large particles, making it suitable for spray application or fertigation.

Equipment used:

Dual Filter System: A two-stage filtration process that removes large solids and fine particulate matter, ensuring the liquid is smooth and free from impurities.

Fine Mesh Filters: Additional filtering can be done to achieve the desired clarity and consistency.

5.Nutrient Fortification

Some liquid fertilizers benefit from additional micronutrients or trace elements like boron, copper, or zinc. This is the stage where nutrients are precisely added to match the needs of specific crops.

Equipment used:

Nutrient Mixing Tanks: Large, high-shear mixers ensure that any added nutrients are evenly distributed throughout the liquid fertilizer.

pH Adjustment System: Automated systems to monitor and adjust the pH of the liquid fertilizer, ensuring it meets the ideal levels for optimal plant absorption.

6.Storage and Packaging

Once the fertilizer is ready, it is stored in tanks and then packaged for distribution. Proper storage is crucial to maintaining the quality of the liquid fertilizer and preventing any nutrient degradation over time.

Equipment used:

Stainless Steel Storage Tanks: These tanks are resistant to corrosion and ensure that the liquid fertilizer remains in ideal condition during storage.

Automatic Filling & Packaging System: For efficient and hygienic packing of the liquid fertilizer into drums, totes, or smaller retail containers.

7.Final Quality Control and Distribution

Before the liquid fertilizer leaves the production facility, a final round of quality control is performed. This ensures that the nutrient content, pH levels, and microbial load are within acceptable ranges.

Equipment used:

Quality Control Lab: A lab equipped with testing instruments to measure nutrient content, pH, and microbial load in the liquid fertilizer.

Batch Tracking Software: Used for traceability, ensuring that each batch of fertilizer meets the required standards.

Agriculture liquid fertilizer production technology involves a precise combination of equipment designed to optimize every stage of the production process. From the use of ultraviolet sterilizers for pathogen sterilization to nutrient fortification and precise pH control, each piece of equipment plays an indispensable role in producing high-quality fertilizers that can meet market demands.

LANE’s comprehensive solution offers customizable systems suitable for various raw materials and processing capabilities. With stainless steel tanks, dual filter systems and energy-saving drying solutions, Lane ensures that the fertilizer production process is as sustainable, efficient and reliable as possible.

Agriculture liquid fertilizer production technology is not a one-size-fits-all solution.Different agricultural systems, waste flows, and nutrient requirements require various methods. The following are the key types of liquid fertilizer production systems used in modern agriculture:

(1) Organic Liquid Fertilizer Production

Organic liquid fertilizers are derived from natural materials such as animal manure, plant extracts, and compost tea. These systems typically involve anaerobic or aerobic fermentation processes, in which organic matter is broken down into nutrients that are usable by plants. The advantage of organic liquid fertilizers is that they provide slowly released nutrients, which can improve soil health over time.

Example Technology:

Compost and fermentation tanks: These storage tanks provide both aerobic and anaerobic conditions to effectively break down organic waste, thereby generating nutrient-rich liquid.

(2) Inorganic Liquid Fertilizer Production

Inorganic liquid fertilizers are produced by dissolving water-soluble nutrients (such as ammonium nitrate, potassium nitrate or phosphoric acid) in water. This method provides rapid nutrient release, which is highly effective for crops with rapid growth cycles (such as vegetables and row crops).

Example Technology:

Mixing and Dissolving Tank: Carefully mix the inorganic salts and dissolve them in the large mixing tank to ensure complete dissolution, thereby producing an immediately usable nutrient solution.

(3) Hybrid Liquid Fertilizer Systems

The mixed system combines organic materials and inorganic materials to produce a balanced fertilizer, thereby providing a direct and long-term release of nutrients. These systems typically meet the growing demand for more sustainable agricultural practices, thus offering farmers the flexibility to meet the needs of various crops.

Example Technology:

Dual-feed system: These systems combine organic extracts and soluble inorganic salts together, thereby customizing the nutrition according to the needs of the crops.

In Indonesia, a rice farm in West Java struggled with inconsistent fertilizer application and nutrient loss due to heavy rainfall. The farm decided to implement LANE’s agriculture liquid fertilizer production technology to improve nutrient efficiency and increase crop yields.

Optimizing Fertilizer Use

Previously using granular fertilizers, the farm faced issues with labor-intensive application and nutrient runoff during the wet season. By installing LANE’s liquid fertilizer production system, the farm shifted to locally produced organic liquid fertilizers made from animal manure and crop residues. This system allowed for precise nutrient blending, tailored to the specific needs of the rice crops.

After one growing cycle:

Rice yield increased by 15% due to better nutrient uptake.

Fertilizer costs were reduced by 22% with more efficient applications.

Nutrient runoff decreased by 30%, improving environmental sustainability.

The farm also began producing liquid fertilizer for nearby farms, opening a new revenue stream. With LANE’s technology, they enhanced both profitability and environmental impact.

Custom Engineering – Systems tailored for feedstock type, capacity, and nutrient goals.

Energy Efficiency – Advanced mixing and heating designs reduce operational costs.

Durability – Stainless steel, anti-corrosion construction ensures a long equipment life cycle.

Automation Ready – PLC-controlled systems with remote monitoring.

Global Service Network – Installation, operator training, and technical support across continents.

Compliance Expertise – Designs meet ISO, CE, and local agricultural safety standards.

| Challenge | LANE Solution |

| Settling of Nutrients | Continuous circulation tanks to keep solutions homogeneous |

| Pathogen Concerns in Organics | Built-in sterilization and pasteurization modules |

| Corrosion from High Salinity | Food-grade stainless steel and specialized coatings |

| pH Imbalance in Blends | Automated pH monitoring and adjustment systems |

| Storage Stability | Anti-foam and stabilizing agents integrated into blending process |

Agriculture liquid fertilizer production technology offers farmers a way to increase yields, cut costs, and protect the environment — all while staying competitive in a rapidly evolving agricultural landscape. Whether the goal is producing organic liquid fertilizers from waste or blending high-performance nutrient solutions, LANE’s systems deliver efficiency, reliability, and customization. The future of farming will be built on smart, sustainable nutrient management, and liquid fertilizer technology is at the heart of that transformation.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.