Advanced Foliar Spray Liquid Fertilizer Production Equipment for Modern Agriculture

The agriculture industry is undergoing a transformation. Farmers are shifting from traditional input-heavy methods to precision solutions that maximize efficiency and sustainability. Among these, foliar spray liquid fertilizers are becoming indispensable. Applied directly to leaves, they ensure rapid nutrient absorption, reduce soil dependency, and deliver higher crop yields. To meet this growing demand, enterprises worldwide are investing in foliar spray liquid fertilizer production equipment, which enables the manufacture of stable, high-quality, and customizable formulations.

This article explores the importance of foliar fertilizers, the raw materials required, the complete production process with accurate equipment usage, and why modern plants are choosing integrated solutions for long-term growth.

Unlike soil-applied fertilizers, foliar sprays bypass the soil medium and deliver nutrients directly through leaf stomata and cuticles. This method is particularly effective when:

Soil conditions limit nutrient uptake (e.g., salinity, pH imbalance).

Plants need quick correction of deficiencies (e.g., zinc, iron, manganese).

Farmers aim for efficient use of fertilizers with less environmental loss.

Crops are in critical growth phases and require immediate nutrition.

The combination of rapid effect and high efficiency is driving demand for reliable foliar spray liquid fertilizer production equipment worldwide.

The selection of raw materials determines both the effectiveness and stability of the final product.

| Raw Material | Function in Fertilizer |

|---|---|

| Nitrogen, Phosphorus, Potassium sources (Urea, MAP, KNO₃) | Core macronutrients for plant growth |

| Micronutrients (Zn, Fe, Mn, B, Cu) | Correct deficiencies and enhance yield quality |

| Chelating Agents (EDTA, DTPA, EDDHA) | Stabilize micronutrients, increase absorption |

| Organic Stimulants (Amino acids, Humic acid, Seaweed extract) | Improve plant resilience and metabolic activity |

| Surfactants / Wetting agents | Enhance leaf coverage and penetration |

| Stabilizers & Preservatives | Prevent precipitation, improve storage life |

| Water (treated or deionized) | Solvent and carrier medium |

(1) Raw Material Dissolving: The process starts with nutrient salts such as urea, potassium nitrate, and micronutrient powders being introduced into a dissolving tank. With heating and constant agitation, these materials dissolve quickly, forming a uniform base solution.

(2) Chelation and Stabilization: The liquid is then transferred to a stainless steel reaction tank. Here, chelating agents are added to stabilize micronutrients like zinc and iron. This step prevents unwanted precipitation, ensuring nutrients remain soluble and effective for foliar spraying.

(3) Blending and Additive Integration: Next, the solution moves into stainless steel mixing tank equipped with a high-speed agitator. Macronutrients, amino acids, seaweed extracts, and other organic stimulants are blended. Surfactants and wetting agents are introduced through an automatic dosing system to enhance leaf penetration and spraying efficiency.

(4) Filtration and Homogenization: To achieve purity and prevent nozzle blockages, the liquid passes through a dual filter system such as a multi-layer mesh filter or plate and frame filter press. Following this, an inline homogenizer ensures consistent particle size distribution and prevents stratification during storage.

(5) Quality Control and Storage: Before moving forward, quality checks are performed to verify solubility, pH, and nutrient balance. Approved batches are transferred into stainless steel storage tanks, which maintain the fertilizer’s integrity until packaging.

(6) Final Packaging: In the last stage, an automatic liquid fertilizer packing machine fills the product into bottles, jerry cans, or IBC tanks. Each container is sealed, labeled, and prepared for distribution, delivering a foliar spray liquid fertilizer ready for agricultural use.

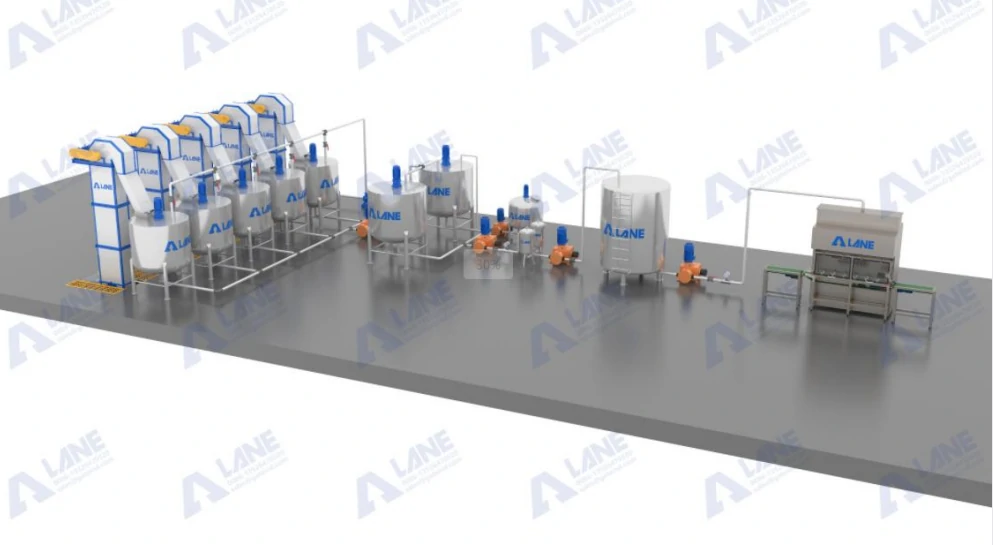

When setting up a foliar spray liquid fertilizer production plant, choosing the right partner is crucial. LANE delivers:

Tailored Plant Design – Customized layouts based on production capacity, raw material sources, and target market.

Cutting-Edge Equipment – Energy-efficient, corrosion-resistant machinery designed specifically for liquid fertilizer formulations.

Turnkey Service – From engineering design and installation to training and after-sales technical support.

Global Experience – Decades of expertise in fertilizer production projects across multiple continents.

Innovation-Driven Approach – Integration of smart control systems, IoT monitoring, and energy-saving technologies.

The next decade will see foliar sprays evolve into multi-functional crop solutions. Instead of only delivering nutrients, they will integrate biostimulants, microbial extracts, and nanotechnology for targeted plant health improvement. Foliar spray liquid fertilizer production equipment will adapt with more automation, AI-driven process control, and smart packaging to support precision agriculture.

Investing in foliar spray liquid fertilizer production equipment is a strategic step for agribusinesses aiming to serve the fast-growing demand for efficient and sustainable crop inputs. From raw material dissolving to advanced packaging, every stage of the process requires specialized equipment to ensure consistency, stability, and market competitiveness. With the expertise and innovation offered by LANE, setting up a reliable production plant becomes not just an investment—but a gateway to future-ready agriculture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.