250ml-300ml Chemical Liquid Fertilizer Production Line Equipment – Small-Bottle, Big Impact

In modern agriculture, 250ml-300ml chemical liquid fertilizer production line equipment plays a crucial role in meeting the increasing demand for small-bottle liquid fertilizers. These compact packaging options are highly suitable for gardening, greenhouse cultivation, home gardening, and export markets. Farmers and suppliers benefit from their convenience, precise application, and strong retail appeal.

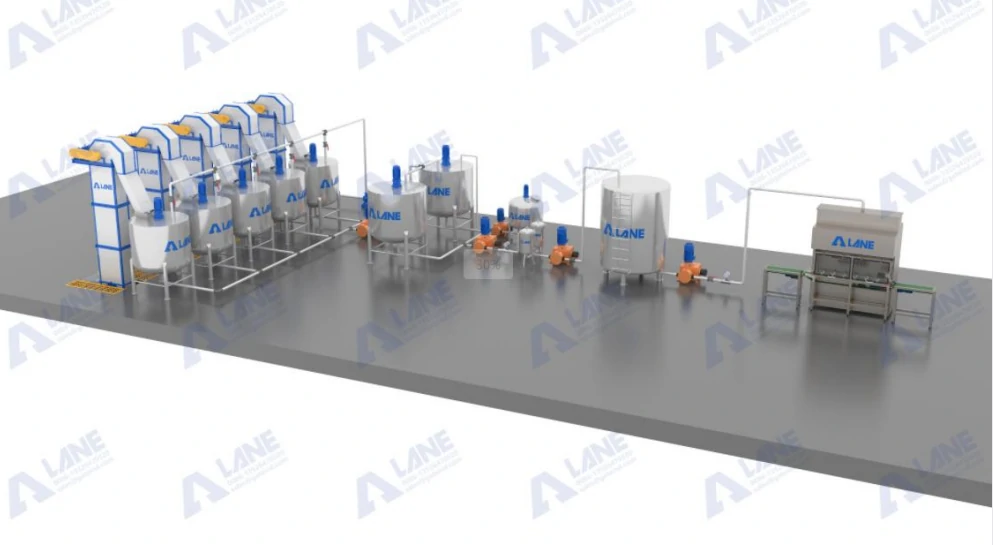

LANE designs advanced small-bottle chemical liquid fertilizer production line equipment, featuring highly automated operation, customizable production capacity, and strict quality control. Our system focuses on efficiency, helping fertilizer manufacturers produce stable and market-demanding products while minimizing operating costs to the greatest extent.

The demand for small-bottle chemical liquid fertilizer production (including the popular 250ml to 300ml packaging sizes) in both domestic and international markets is growing rapidly. These compact packages are not only convenient but also represent an intelligent, market-driven method of fertilizer distribution.

The small-bottle chemical liquid fertilizer production provides farmers, gardeners and greenhouse operators with an easy-to-use and precisely-measured solution, which can reduce waste and improve the efficiency of nutrient application. The small bottle liquid fertilizer has strong shelf appeal and a convenient transportation design, making it an ideal choice for supermarkets, agricultural supply stores and export trade. Retailers also benefit from it.

From a manufacturing perspective, the production of small-bottle fertilizers offers opportunities to enhance product diversity, provide precise crop solutions, and build high-end brands. In areas where agricultural land is scattered or where farmers manage small plots of land, small-packaged fertilizers have become the preferred choice due to their affordability and convenience.

In short, small-bottle chemical liquid fertilizer production is not only about packaging size, but also about meeting the demands of the constantly changing agricultural landscape and maintaining competitiveness in the global fertilizer market.

Producing high-quality small-bottle chemical liquid fertilizer—whether in 250ml, 300ml, or similar sizes—starts with selecting the right raw materials. Each ingredient plays a specific role in ensuring that the final product delivers consistent nutrients, maintains stability during storage, and supports optimal plant growth.

1. Macronutrients – The Foundation of Fertilizer

The primary nutrients—Nitrogen (N), Phosphorus (P), and Potassium (K)—form the backbone of most liquid fertilizer formulations. Nitrogen promotes leafy growth, phosphorus supports root development, and potassium improves overall plant health and resistance.

2.Micronutrients – The Growth Boosters

Essential trace elements like Iron (Fe), Zinc (Zn), Manganese (Mn), Boron (B), and Copper (Cu) are critical for plant enzyme activity and disease resistance. Even in small quantities, they make a big difference in crop quality and yield.

3.Organic Additives – For Soil and Plant Vitality

Additives such as humic acid, fulvic acid, and seaweed extract improve soil structure, stimulate root growth, and enhance nutrient absorption. They are especially valuable in small-bottle chemical liquid fertilizers targeted at high-value crops.

4.Chelating Agents – Ensuring Nutrient Availability

Chelates like EDTA and DTPA protect micronutrients from becoming inactive in the soil, ensuring they remain available for plant uptake.

5.Stabilizers and Preservatives – Extending Shelf Life

To keep the fertilizer fresh and effective over time, stabilizing agents maintain the correct pH, while preservatives prevent microbial growth in the liquid formulation.

6.Water – The Universal Carrier

Clean, filtered water is the base of every liquid fertilizer. It ensures that all ingredients dissolve properly and that the final product has the right consistency for both manual and automated application systems.

By combining these components in precise proportions, the small-bottle chemical liquid fertilizer production line can produce formulations that meet the specific needs of crops, regional soil conditions, and market preferences. Whether for local agricultural communities or international exports, choosing the right raw materials is the key to providing fertilizers that farmers trust and meet the demands of buyers.

The production of small-bottle chemical liquid fertilizers (including 250ml and 300ml specifications) requires precise and automated processes to ensure product consistency, stable nutrition and high-quality packaging. The detailed workflow of LANE’s advanced production line is as follows:

1.Raw Material Preparation & Measuring

High-purity macronutrients (NPK), micronutrients, and organic additives are prepared and weighed according to the fertilizer formula.

LANE uses automatic stainless steel dosing systems to ensure every ingredient meets the exact specification. This guarantees consistent nutrient content across every batch.

2.Dissolving & Pre-Mixing

Ingredients are introduced into stainless steel mixing tanks filled with filtered water. Controlled heating (if required) helps dissolve solid components like potassium nitrate or urea.

Pre-mixing ensures that all components are evenly dispersed before final homogenization.

3.Homogenization – Creating a Uniform Fertilizer Solution

The pre-mixed liquid is processed in a LANE high-shear homogenizer, breaking down particles to create a smooth, lump-free fertilizer solution.

This step is critical for small-bottle packaging, as any undissolved particles could affect filling accuracy and clog application equipment.

4.Filtration & Purification

The fertilizer solution passes through a dual filtration system that removes impurities, preventing nozzle blockages and ensuring product clarity.

This step is especially important for export-grade small-bottle chemical liquid fertilizer where appearance and purity are critical.

5.Quality Testing & Formula Verification

Samples from each batch undergo laboratory testing for:

Nutrient content (NPK ratio)

pH value

Density and viscosity

Microbial contamination check

Only batches that meet international quality standards move to the bottling stage.

6.Automatic Bottle Filling

LANE’s automatic small-bottle filling machines precisely dispense fertilizer into 250ml and 300ml PET or HDPE bottles. The high-precision filling system minimizes spillage and maintains uniform volume in every bottle.

7.Capping, Labeling & Final Packaging

Once the bottles are filled, they move seamlessly into the capping and sealing stage, where automatic screw capping machines or heat induction sealing equipment secure each 250ml–300ml bottle for leak-proof storage and transport. Next, bottles enter the automatic labeling system, where durable, moisture-resistant labels are applied, displaying essential product information, branding, and usage instructions. For many clients, LANE also offers custom branding to help products stand out in competitive markets. Finally, labeled bottles are packed into sturdy cartons using carton sealing and packing machine. This ensures that every shipment of small-bottle chemical liquid fertilizer production is well-protected, easy to handle, and ready for distribution to agricultural suppliers, retail stores, or export channels.

8.Storage & Distribution

The finished small-bottle chemical liquid fertilizers are stored in a controlled warehouse environment before being distributed to agricultural supply chains, retail stores, and export markets.

| Equipment | Capacity | Material | Key Features |

| Automatic Dosing System | Up to 5000 kg/hr | Stainless Steel | High precision, programmable controls |

| Stainless Steel Mixing Tank | 2000 L | Food-grade Stainless Steel | Heating & cooling options, corrosion resistant |

| High-Shear Homogenizer | 500 L/min | Stainless Steel | Uniform mixing, particle size reduction |

| Dual Filtration System | 2-stage filtration | Stainless Steel | Removes impurities, protects filling nozzles |

| Automatic Small-Bottle Filling Machine | 250ml-300ml bottles, up to 3000 bottles/hr | Stainless Steel | Accurate filling, minimal spillage |

| Automatic Capping Machine | Up to 150 bottles/min | Stainless Steel | Leak-proof sealing, adjustable torque |

| Automatic Labeling System | 200 bottles/min | Stainless Steel | High-precision label placement, moisture-resistant labels |

| Carton Sealing & Shrink Wrapping Machine | Up to 100 cartons/hr | Steel | Secure packaging, damage protection |

Each piece of equipment is designed to optimize efficiency and maintain the highest quality standards needed for small-bottle chemical liquid fertilizer production. Using stainless steel and food-grade materials ensures durability and safety. Automation in dosing, filling, and packaging reduces labor costs and human error, helping you produce competitive products at scale.

Small-bottle chemical liquid fertilizers, especially the popular 250ml to 300ml sizes, have become essential products in various agricultural and horticultural fields due to their convenience and precise fertilization. Their application areas include:

Horticulture and greenhouses: Perfect for flower cultivation, vegetable nurseries, and environmentally controlled agriculture, where precise nutrient management is crucial.

Urban gardening: Ideal for small gardens, potted plants, and balcony crops, providing easy-to-use fertilization solutions for home gardeners.

Export trade: Compact packaging and standardized bottle sizes make these fertilizers highly suitable for global supermarkets and agricultural supply chains.

Specialty crops: Widely used in vineyards, coffee plantations and medicinal plant farms where customized fertilizer formulas and stable quality are required.

Case Study 1 – European Garden Supply Company

A leading garden supply business in Europe integrated LANE’s small-bottle chemical liquid fertilizer production line. This upgrade doubled their packaging capacity, allowing them to expand their export reach into three additional European Union countries within a year. The increased efficiency and packaging quality helped them capture new markets and boost revenue.

Case Study 2 – Middle East Greenhouse Fertilizer Supplier

A prominent fertilizer supplier serving greenhouses in the Middle East adopted LANE’s automated production system. This transition resulted in a 45% increase in production efficiency and a 30% reduction in labor costs. Moreover, the supplier successfully diversified their product range, catering to various export demands with customized fertilizer formulas.

Q1: Can the equipment handle different types of fertilizers?

Absolutely. LANE’s production lines are versatile and capable of manufacturing organic, chemical, and blended liquid fertilizers, accommodating a wide range of formulations.

Q2: Is it possible to produce bottle sizes other than 250ml-300ml?

Yes. The production line is flexible and can be adjusted to handle various bottle capacities to suit specific market needs.

Q3: Are the systems suitable for export markets?

Definitely. All LANE equipment meets international standards with CE and ISO certifications, ensuring compliance and reliability in global trade.

As demand for small-bottle chemical liquid fertilizers grows worldwide, LANE’s chemical liquid fertilizer production line equipment delivers unmatched automation, accuracy, and adaptability. Whether serving local retail outlets, expanding into export markets, or focusing on specialty crops, LANE provides comprehensive turnkey solutions. From initial plant design and equipment installation to operator training and after-sales support, LANE empowers manufacturers to meet production goals efficiently and profitably.

Choose LANE to transform your small-bottle chemical liquid fertilizer production into a successful business venture.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.