Building a 10t/h Amino Acid Liquid Fertilizer Production Line in India: A Simple and Real Story

India is a country where farming is part of daily life. From large green fields to small family farms, crops are everywhere. In recent years, many farmers have started to look for better and easier ways to improve soil and crop growth. Because of this, the idea of building a 10t/h amino acid liquid fertilizer production line in India has become more popular and meaningful.

When people first hear this long name, it may sound difficult. But in fact, the idea behind a 10t/h amino acid liquid fertilizer production line in India is very clear. It is simply about making liquid fertilizer in a steady and organized way, so farmers can get what they need on time and at a good price.

India has a warm climate, long farming seasons, and a large demand for fertilizer. Many farmers prefer liquid fertilizer because it is easy to use and works fast. This makes a 10t/h amino acid liquid fertilizer production line in India a smart choice.

At the same time, factories in India often need simple and strong equipment. Power supply may not always be stable, and workers may come from different skill levels. So the production line should be easy to understand and easy to operate. These local conditions shape how the whole line is designed.

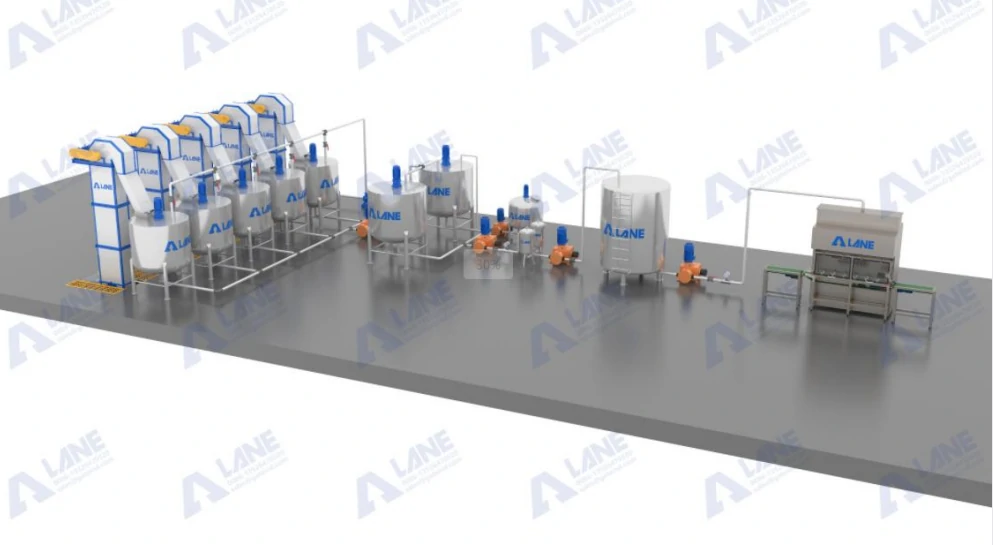

A 10t/h amino acid liquid fertilizer production line in India does not need to be full of complex machines. The main idea is to mix materials, store the liquid, and then pack it. Every step follows the next one naturally.

First, raw materials arrive at the factory. They are usually liquids or powders that can dissolve in water. These materials are placed into storage tanks. The tanks should be strong and well-sealed, especially because India’s weather can be hot and humid.

Mixing is the key step in a 10t/h amino acid liquid fertilizer production line in India. The mixer’s job is simple: make sure everything blends evenly. A good mixer runs smoothly and does not stop easily.

In many Indian factories, workers prefer machines that are easy to clean and check. A simple control system helps workers see if the mixer is running well. This reduces mistakes and keeps production moving.

After mixing, the liquid fertilizer goes into storage tanks. These tanks hold the product before it is packed. For a 10t/h amino acid liquid fertilizer production line in India, storage tanks should be placed in a safe and shaded area if possible.

Local factory owners often think about long-term use. Tanks that are easy to repair with local tools are more popular. This practical thinking helps save money and time.

Pumps and pipelines connect the whole 10t/h amino acid liquid fertilizer production line in India. They move liquid from one step to another. Even though they look simple, they are very important.

The pumps should be strong and stable. Pipelines should be arranged clearly, so workers can understand them at a glance. This is very helpful in busy production environments.

Once the liquid fertilizer is ready, it needs to be filled into containers. Packing machines help complete this step quickly and evenly. In a 10t/h amino acid liquid fertilizer production line in India, accuracy is important, but the machine does not need to be complicated.

After filling, packing is often done by hand. This creates jobs and fits well with local working habits. Many factories in India prefer this mix of machines and manual work.

In some areas, power cuts can happen. So a 10t/h amino acid liquid fertilizer production line in India should be easy to restart. Machines that can return to their settings quickly are very useful.

Water is also needed for cleaning. A simple water system near the production line makes daily work much easier. Good lighting and clear walking paths also help improve safety and efficiency.

As LANE, we have worked in the fertilizer machinery field for over 20 years. Our company understands that every country has its own needs. When we support a 10t/h amino acid liquid fertilizer production line in India, we focus on simple design and stable operation.

We provide complete solutions, from design to installation. We follow ISO 9001 and CE standards, and we always stay in touch after the line starts running. At LANE, we believe good service and clear communication are just as important as good machines.

Building a 10t/h amino acid liquid fertilizer production line in India is not only about today’s production. It is about helping farmers in the next season and beyond. When the line is easy to use and reliable, everyone benefits.

Factories grow, farmers gain confidence, and local agriculture becomes stronger. This is how small steps can lead to long-term progress.

In the end, a 10t/h amino acid liquid fertilizer production line in India is a practical and realistic project. It fits local conditions and real needs. With the right equipment and support, it becomes a solid foundation for better farming and a better future.

For more details, please feel free to contact us.

Henan Lane Heavy Industry Machinery Technology Co., Ltd.

Email: sales@lanesvc.com

Contact number: +86 13526470520

Whatsapp: +86 13526470520

Leave a Comment

LANE has more than 500 successful cases and is committed to providing customers with first-class solutions, high-end machinery and equipment, and one-stop pre-sales, sales and after-sales comprehensive customer service.